+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

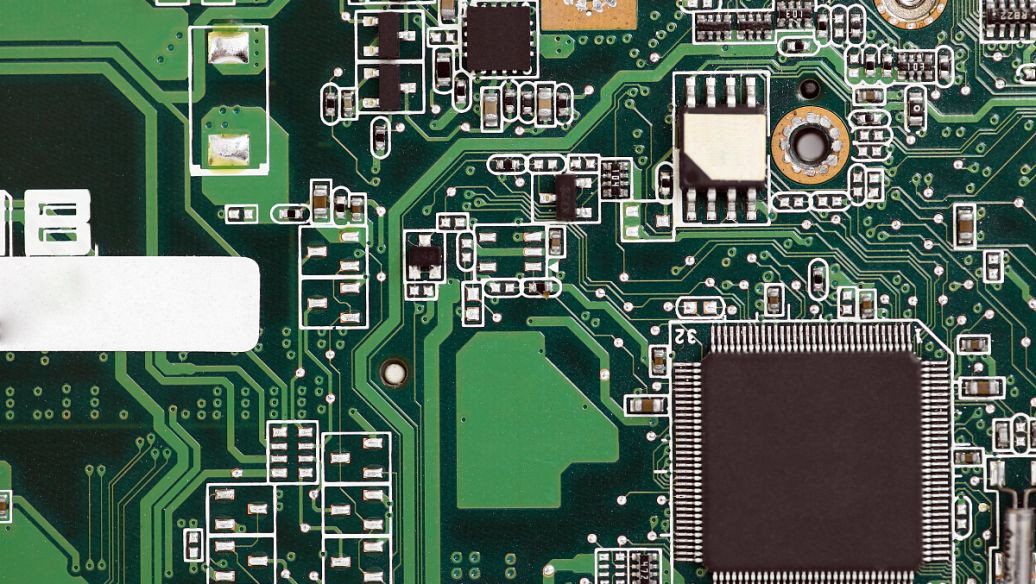

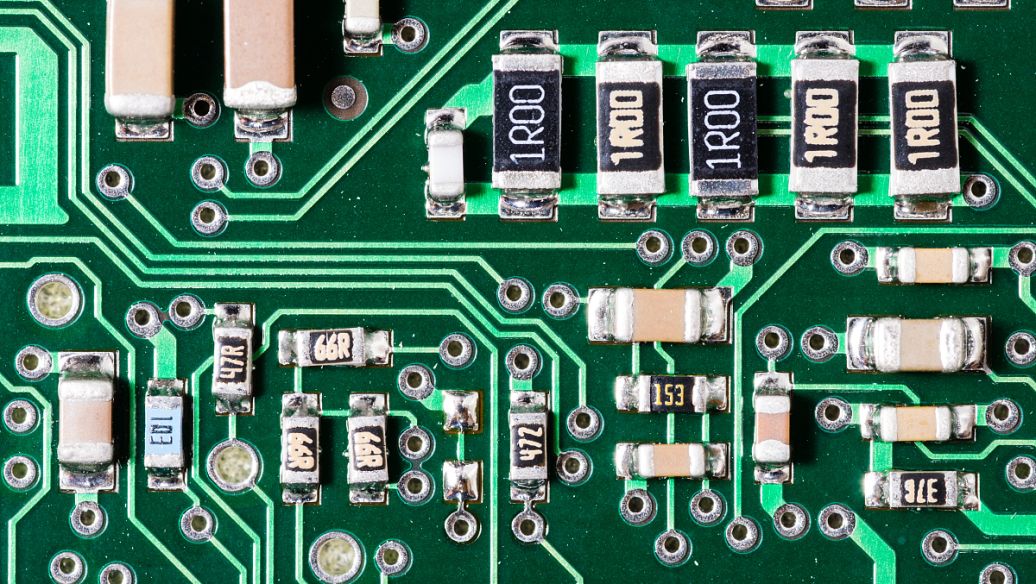

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

PCB connector This bottom contact connector has specifications of 4 to 8 circuits, with a rated current and voltage of 0.3A and 50V, and can be used for 0.12mm thick FPC cables. It has a unique BackFlip clamp that facilitates the insertion and extraction of cables in tight spaces, as well as strong FPC cable clamping force. The PCB connector industry in Chinese Mainland is one of the few regions not affected by the global economic recession. As the domestic and international market demand is strong, with the development of electronic equipment to higher transmission speed and smaller size, connectors also follow this trend. Therefore, chip connectors, optical fiber connectors Connector products such as wired broadband connectors and micro spacing connectors suitable for various portable/wireless electronic devices are expected to become future star products.

PCB series connectors: used in military aviation, railway projects, industrial projects, aerospace projects, testing instrument ship systems, electric sightseeing vehicles; UPS; Communication power supply; The preferred high current connector for products such as chargers and batteries. The connector is made of PBT material, which has excellent electronic and motor characteristics and can be widely used in industrial needs. Various electric vehicles, including electric buses, forklifts, golf carts, sightseeing vehicles, tractors, batteries, communication power supplies; UPS. AC/DC stabilized power supply. EPS. inverter, high-frequency module power supply and high-frequency charger system, electric machinery; Electric wheelchairs, electric floor scrubbers, lawn mowers, vacuum cleaners, medical equipment; Suction machines, pressure reducing machines, electric treatment beds; Power supply, Material-handling equipment, rechargeable battery application, power distribution equipment, indu

The insulation is made of German Bayer flame-retardant polycarbonate raw materials, ensuring your safe use. The plastic base shall prevent unqualified phenomena such as extrusion deformation and long-term fracture. After secondary manual inspection of the screws and nuts, there will be no signs of screw jamming, slipping, and difficulty in disassembly. The terminal connection piece is free of burrs, patterns, secure clamping, good coating, excellent conductivity, and good verticality of the connection piece. This product adopts a wire spring contact pair, and the socket automatically shortens when the plug and socket are separated by 4mm. This product has high reliable electrical contact performance, novel structure, convenient use, small size, soft insertion and extraction, long service life, low contact resistance, good insulation performance, anti-interference, and other characteristics. Widely applicable to electrical control equipment in power system relay protection control

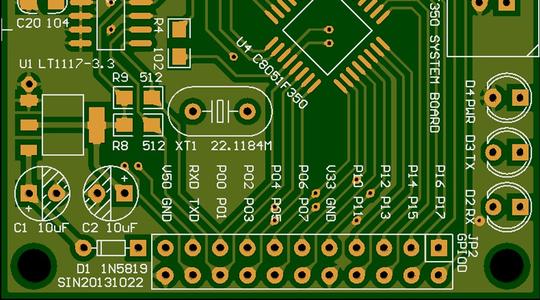

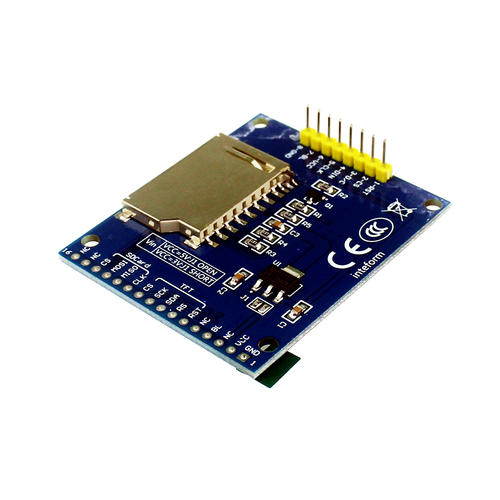

Its working principle is: usually, a conductive pattern made of printed circuits, printed components, or a combination of both on insulating materials according to predetermined design is called a printed circuit. The conductive pattern that provides electrical connections between components on an insulating substrate is called a printed circuit. In this way, printed circuits or finished boards of printed circuits are called printed circuit boards, also known as printed boards or printed circuit boards. The gold soldering area on the PCB lowers the PCB board edge In industrial environments, connectors produced using press fit technology can maintain stability and can be used with right angle PCBs This nano compact connector is suitable for various drones, especially in extremely harsh working environments The advantage of using this connector in drone applications is that the oversupply of basic PCB connectors with small size has forced their prices to decrease by 3% to 10%. Manuf

The product meets the 19 "standard and adopts a splicing method of profiles and plates, which is easy to assemble and fully reflects the characteristics and advantages of standardization, modularization, and serialization. The product adopts a modular card structure with good scalability, which can be expanded according to customer needs and is easy to maintain in the later stage. Has good electromagnetic shielding performance. For special functional requirements such as EMC (electromagnetic shielding and anti-interference) and ESD (live plug and unplug maintenance), both design and functionality have passed product testing certification. It has reliable anti strength vibration design, impact design, and load-bearing design (superior performance in rail transit). Excellent heat dissipation performance and environmental protection design (IP protection level). Effective lightweight design: The product is made of aluminum alloy material, which is lightweight and effective, and has

Circuit board moisture-proof insulation coating adhesive is specifically designed for PCB circuit boards and various plastic surfaces to provide protection after coating. The surface of the covered material has functions such as moisture resistance, insulation, dust prevention, and corona prevention. Typical applications include PCB circuit boards, solar panels, bathroom sensors, ink, paper drawings, and more 1. There are a wide range of bonding materials, suitable for various circuit board substrates, plastics, glass, and metals. Oil coated paper and other materials have extremely high adhesion 2. The surface of the adhesive solidifies (surface drying) quickly, and can quickly reach surface drying under ultraviolet light irradiation. 3. It can cover the surface of PCBs, soft plastics, and oil coated paper paintings 4. Low viscosity and permeability, which can be sprayed mechanically 5. It is moisture-resistant, high-temperature resistant, high humidity resistant, and UV resis

1. The ideal adhesive layer thickness for bonding is 0.01-0.05mm, and either too thin or too thick can affect the bonding performance. 2. Ensure that the adhesive layer absorbs sufficient ultraviolet energy to achieve the best curing effect, otherwise it may affect the adhesive performance of the adhesive layer. 3. Do not move the material back and forth when exposed to ultraviolet radiation, otherwise it may cause the adhesive layer to turn white and the bonding strength to decrease. 4. The remaining glue should not be returned to the original packaging, and should be stored at room temperature and sealed away from light, avoiding contact with children. 5. This product has slight irritation to the eyes and skin. If it accidentally splashes into your eyes, please rinse immediately with plenty of water. If in contact with skin, Rinse with soap. If the situation is serious, please see a doctor. It is recommended that the glue applicator wear professional UV resistant glasses and

Plastic circuit boards are another type of thermoplastic engineering plastic circuit board compared to the traditional thermosetting epoxy resin fiberglass that is widely used in the electronics industry. Traditional printed circuit boards are made by die-casting thermosetting resin and glass fiber into a substrate, and then bonding conductive copper foil onto the substrate. It is called printed circuit copper clad plate. Copper clad boards are made into printed circuit boards through processes such as exposure and etching. This process has armed the electronics industry to this day. However, the process of removing copper foil involves environmental issues, and approval of circuit board licenses is strictly prohibited in many regions. Printed circuit boards are a planar structure, although flexible circuit boards can be formed on curved surfaces as a branch, they are not rigid curved three-dimensional structures. Some emerging applications, such as robots, 3D lighting fixtures, a

Inquiry Now