+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

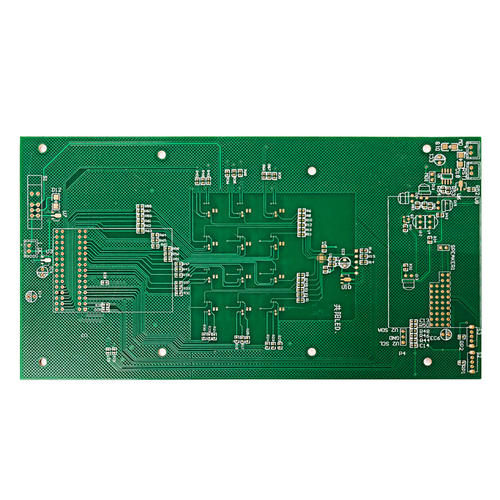

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

(1) Visual inspection PCB boards generally undergo electrical testing before leaving the factory. We inspect the appearance of PCB boards through visual inspection methods upon receipt, including warping, scratches, flying wires, broken wires, ink blockage, unclear screen printing, solder pad oxidation, uneven solder pads, blocked vias, and burrs on the board edges (2) Dimensional measurement Use a micrometer to measure the thickness, shape, dimensions, and V-CUT of the PCB board to ensure compliance with the Gerber file design. (3) Furnace temperature test Many PCB boards, due to poor process control, experience yellowing and warping when subjected to high temperatures such as reflow soldering. When outsourcing processing, it is essential to require the PCB board to undergo furnace temperature testing first to avoid mass welding defects or affecting the future reliability and durability of the product. Especially for PCB boards with high TG design, this inspection is particular

After the electronic product development project is finalized, engineers and procurement departments need to estimate the price of the entire PCBA circuit board. The simple method is to send the design BOM and GERBER files to different suppliers to obtain quotations for comparison. But the problem is that when there is a significant difference in the price of PCBA we obtain, we cannot determine the true and accurate price. Because different suppliers may substitute materials or make random estimates, which can mislead your prices. At this time, it is particularly important to self estimate the price of PCBA processing. PCBA processing price mainly includes: component cost, PCB cost, SMD processing cost, and basic Gross profit of manufacturing enterprises. The cost of components can be inquired through the public Open platform (Tradegate, Datagate), and its open price can be used as a reference. For large goods above 10K, it can generally be estimated at 70% of the open price. The

The steel mesh tension standard has reference indicators in the IPC electronic acceptance standard. Generally, a steel mesh tension tester is used, placed at a distance of 15-20cm from the edge, and 5-8 points are selected, with each square centimeter having a tension greater than 35-50N. Every time the steel mesh is used online, the tension must be re measured. The testing steps are as follows: Appearance inspection of steel mesh: whether there are scratches, burrs, damages, etc Zero the tension gauge and tighten the zero scale screw The steel mesh should be placed horizontally on the workbench and should not be pressed by hand during testing Select a Test point to check whether the test value meets the standard Fill out the "Steel Mesh Tension Test Record Form" Steel mesh cleaning Installation and use on solder paste printing machine

1. Does the voltage and current meet the design requirements Under normal circumstances, after each PCBA is powered on, even without burning the MCU program, various voltage differences, current conduction, etc. can be generated through circuit connections. PCB designers will deploy different Test point on the PCBA board, and these Test point can be connected to the ICT or FCT test rack to detect voltage and current data. 2. After burning MCU program, input user actions and check whether the output is normal After the PCBA board burns the MCU program, the user executes an action (such as long pressing the switch for 3 seconds), and the MCU will issue a logic command to control the circuit's switch, thereby achieving the design requirements. In this case, PCBA online test can detect whether the input and output of this action are normal. 3. Full functional testing at the product level This online testing is relatively advanced, basically simulating more than 80% of the core fun

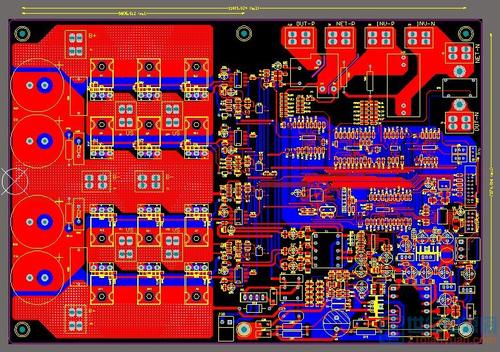

Engineering and technical personnel should understand the necessary production processes and master relevant software production, including common circuit design software such as Altium Designer, Pads2000, Autocad, etc. They should also be familiar with necessary CAM software such as View2001 and CAM350; GCCAM, etc., should include PCB design input, which can edit, correct, repair, and assemble circuit graphics, use magnetic disks as the dielectric material, and output automated data for photo drawing, drilling, and testing. An important aspect of the success of the laser light drawing machine market is providing manufacturers with a large amount of technical strength in engineering production. At the same time, we have also seen a large demand for engineering and production personnel from Jianhe PCB manufacturers, as well as an increasing demand for the level of engineering and technical personnel. Therefore, it prompts us to continuously improve our technical level in order to m

The level of PCB engineering production can reflect the design level of designers, as well as the production process and technical level of printed board manufacturers. At the same time, as the PCB engineering production integrates Computer-aided design and auxiliary manufacturing, it requires extremely high precision and accuracy, otherwise it will affect the electrical performance of the final electronic products on board, and may cause errors in serious cases, which will lead to the scrapping of the whole batch of printed board products, delay the manufacturer's contract delivery time, and suffer economic losses. Therefore, as a PCB engineering manufacturer, one must always bear in mind their significant responsibilities and not take them lightly. They must be careful, serious, and meticulous. When processing PCB design files, it is important to carefully check whether the received files comply with the rules established by the designer? Can it meet the requirements of PCB manuf

The circuit board has a history of over 60 years since its invention. History has shown that without circuit boards and electronic circuits, flight, transportation, atomic energy, computers, aerospace, communication, home appliances... all of these cannot be achieved. The truth is easy to understand. Chips, ICs, and integrated circuits are the grain of the electronic information industry. Semiconductor technology reflects a country's level of industrial modernization and guides the development of the electronic information industry. The electrical interconnection and assembly of semiconductors (integrated circuits, ICs) must rely on circuit boards. As the author of Japan's "Circuit Board Collection", Masao Kobayashi, said, "Without computers and data, electronic devices are like an ordinary box; without semiconductors and circuit boards, electronic components are like ordinary stones." PCB is a promising industry in China, with double-digit growth rates every year. Many foreign ord

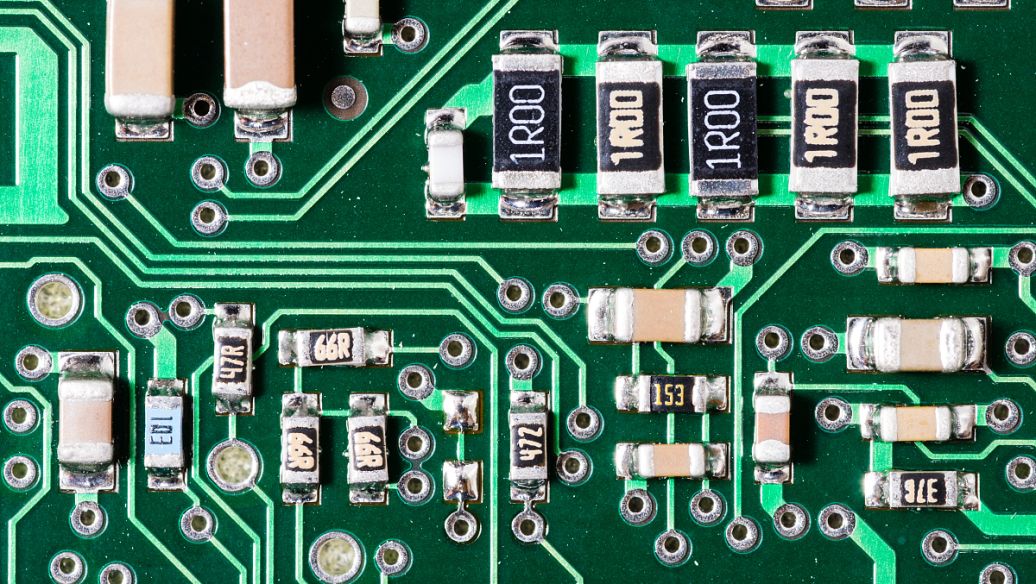

Circuit board maintenance is an emerging repair industry. The automation level of industrial equipment is increasing, so the number of industrial control boards in various industries is also increasing. After the industrial control boards are damaged, the high cost of replacing circuit boards (ranging from several thousand yuan to tens of thousands or hundreds of thousands of yuan) has become a very headache for enterprises. In fact, the vast majority of these damaged circuit boards can be repaired in China, and the cost is only 20-30% of purchasing a new board, which takes much shorter time than ordering a board abroad. Below is an introduction to the basic knowledge of circuit board maintenance. Almost all circuit board maintenance has no drawings and materials, so many people are skeptical of circuit board maintenance. Although various circuit boards are different, what remains unchanged is that each circuit board is composed of various integrated blocks, resistors, capacitors a

Inquiry Now