+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

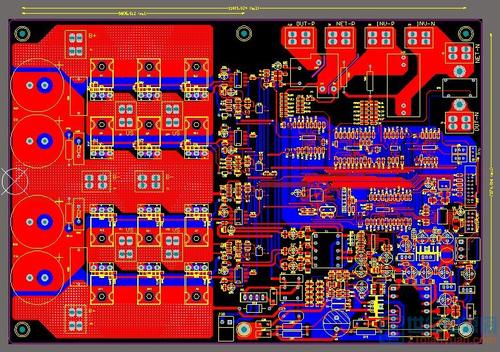

As pcb design is more and more commonly used in existing development boards, and sub boards are used to drive hydraulic devices and servo motors or perform tasks according to light, motion and sound, the design trend of printed circuit boards gradually tends to Open-source hardware mode and control system. Another major trend in PCB design is the explosive growth of development boards. In October 2013, a survey was conducted on PCB designers from around the world, including professional engineers from 42 different countries. The survey results show that nearly two-thirds of the respondents (64%) believe that the development board has to some extent reduced their demand for customized PCB design. On the surface, this result poses a threat to the development of PCB design, but in reality, printed circuit board design tools are being increasingly applied in development board design. However, since its inception, the design of printed circuit boards has not undergone fundamental chang

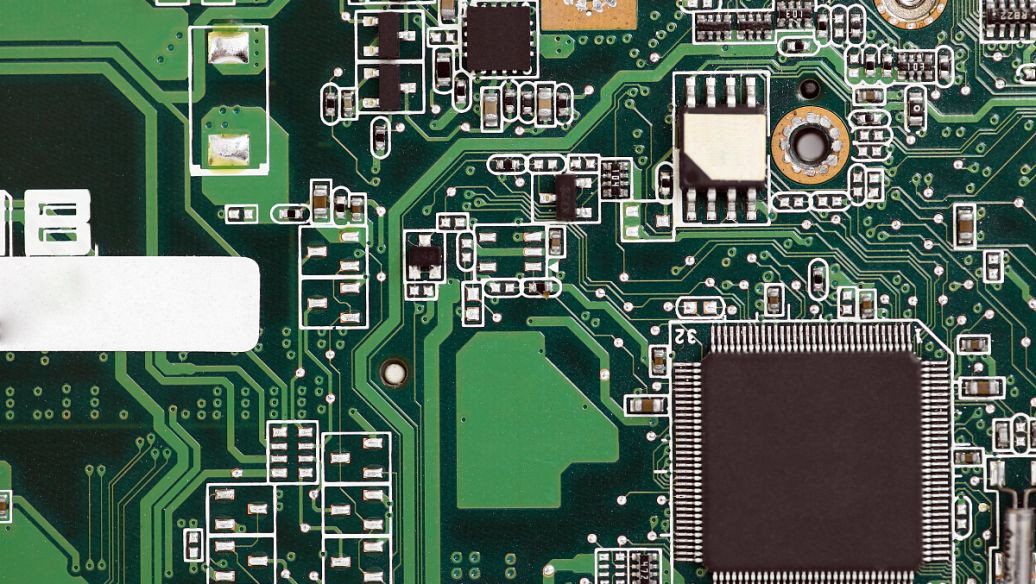

These electronic products aim to save space and make them lighter and more compact. Durable and to achieve good performance, it is necessary to cancel the previous wire connection and switch to a printed circuit board. PCB meets the requirements of space, performance, and reliability. Not every electrical appliance requires a circuit board, simple appliances may not require a circuit, such as an electric motor. However, electrical appliances with specific functions typically require circuit boards to be implemented, such as televisions, radios, computers, etc. There is also a PCB at the bottom of the Rice cooker and a governor in the fan. PCB board usually refers to a hard circuit board, mainly used for computer motherboards, mouse boards, graphics cards, office equipment, printers, copiers, remote controls, various chargers, calculators, digital cameras, radios, TV motherboards for household appliances, limited TV amplifiers, mobile phones, washing machines, electronic scales, t

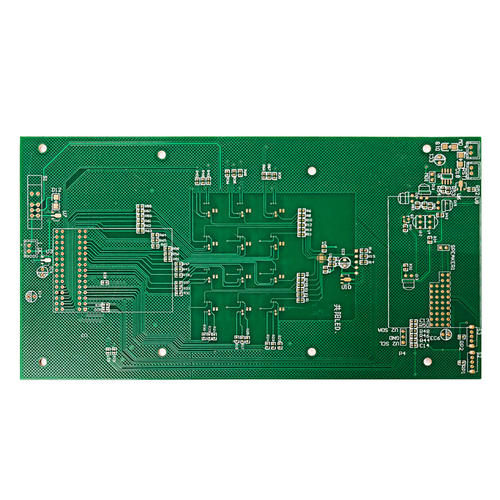

Single sided PCB sample delivery time: Normal delivery time is 2-3 days, and can be expedited within 12 or 24 hours Sample delivery time for double-sided PCB board: Normal delivery time is 2-3 days, and can be expedited within 12 or 24 hours Sample delivery time for the fourth layer circuit board: normal delivery time 4-5 days, with 12, 24, and 72 hours for expedited delivery Six layer circuit board sample delivery time: normal delivery time of 6-7 days, with 72 hours for expedited delivery LED aluminum substrate sample lead time: Normal lead time 3-4 days, can be expedited within 72 hours Delivery time for small batch sampling of PCB circuit boards: 5-6 days within 5 square meters; 6-7 days within 10 square meters; Over 10 square meters for 8-9 days Kind reminder: 1. Except for matte black, matte green, and purple, all other colors are free of charge! 2. Place an order for payment before 18:00 on the same day, and the PCB sample delivery time will be calculated from the ne

In the PCB production process, the reservation of process edges is of great significance for subsequent SMT chip placement processing. The process side is to assist in the welding of the PCB board on both sides or on all four sides of the PCB board. It is mainly used to assist production and is not a part of the PCB board. It can be removed after the completion of PCBA manufacturing and production. Due to the fact that process edges consume more PCB boards, which increases the overall cost of the PCB, it is necessary to balance economy and manufacturability when designing PCB process edges. For some special shaped PCB boards, the original PCB boards with 2 or 4 process edges can be cleverly simplified by splicing. When designing the splicing method in SMT mounting processing, it is necessary to fully consider the track width of the SMT mounting machine. For splicing exceeding 350mm in width, it is necessary to communicate with the SMT supplier's process engineer. The main reason

For some friends who are new to aluminum substrates, there are still questions about the difference between aluminum substrates and PCB boards. Today, the editor will talk to you specifically about this question. Aluminum substrate is a metal-based copper-clad laminate with good heat dissipation function. Generally, a single panel is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. PCB board, also called printed circuit board, is a provider of electrical connections for electronic components. PCB board is a big category, aluminum substrate is only one of the types, and the design is designed in accordance with the requirements of pcb board. The aluminum substrate we generally call is a single-sided aluminum-based PCB board with good thermal conductivity and is generally used in the LED industry. At present, the commonly used LED aluminum substrate has two sides, the white side is for soldering the LED pins, a

Everyone knows that aluminum is a kind of metal and has conductivity. How can it be used as a PCB material? This is because the aluminum substrate is composed of three layers: copper foil, insulating layer and metal aluminum. Since there is an insulating layer, can the metal layer be made of other materials besides aluminum? Such as copper plate, stainless steel, iron plate, silicon steel plate and so on. What kind of material is used for the metal substrate, in addition to considering the heat dissipation performance, but also consider the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface condition and cost of the metal substrate. Under normal circumstances, considering the cost and technical performance, aluminum plate is an ideal choice. Available aluminum plates are 6061, 5052, 1060, etc. If there are higher thermal conductivity, mechanical properties, electrical properties and other special performance requirements, copper plates, stain

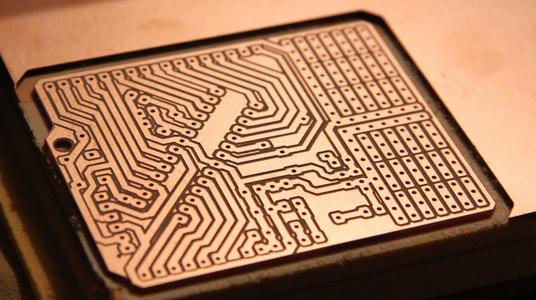

Copper foil is a kind of negative electrolytic material, a thin, continuous metal foil deposited on the base layer of the circuit board, which acts as the conductor of the PCB. It easily adheres to the insulating layer, accepts the printed protective layer, and forms a circuit pattern after corrosion. What is the role of the copper foil of the aluminum substrate? The copper foil of the aluminum substrate is also called the circuit layer of the aluminum substrate. It is the conductor of the aluminum-based circuit board and also a kind of cathode electrolytic material, which is generally deposited on the base layer of the circuit board. Thin, continuous metal foil. Copper foil has low surface oxygen characteristics and can be attached to various substrates, such as metals, insulating materials, etc., and has a wide temperature range. The copper foil of the aluminum substrate is easily adhered to the insulating layer and accepts the printed protective layer. After corrosion, the patt

The good heat dissipation performance of the aluminum substrate makes it widely used. Let the aluminum substrate manufacturers introduce the aluminum substrate in detail below. 1. Features of aluminum substrate 1. Using surface mount technology (SMT); 2. In the circuit design scheme, the heat dissipation is extremely effective treatment; 3. Reduce the operating temperature of the product, improve the power density and reliability of the product, and extend the service life of the product; 4. Reduce product volume, reduce hardware and assembly costs; 5. Replace the fragile ceramic substrate to obtain the best mechanical durability. 2, the structure of the aluminum substrate Aluminum-based copper clad laminate is a metal circuit board material, composed of copper foil, thermally conductive insulating layer and metal substrate: Copper foil: the copper clad laminate equivalent to ordinary PCB, the thickness of the circuit copper foil is loz to 10oz. Thermally conductive insul

Inquiry Now