+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

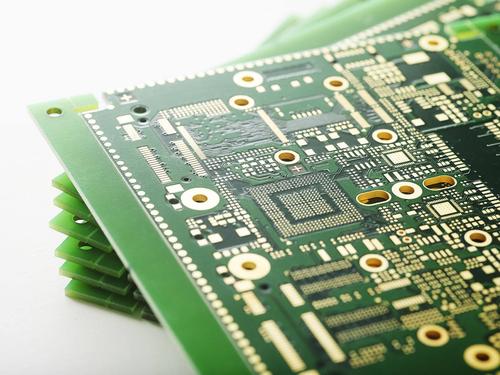

1、 Definition of high-frequency PCB circuit board High frequency PCB circuit boards refer to circuit boards with higher electromagnetic frequencies used in the fields of high frequency (frequencies above 300MHz or band lengths not exceeding 1m) and microwave (frequencies above 3GHz or wavelengths not exceeding 0.1m). It is a circuit board produced using ordinary rigid circuit board manufacturing methods or special processing methods on microwave based copper clad plates. Generally speaking, high-frequency circuit boards can be considered as circuit boards with frequencies above 1GHz. With the rapid development of science and technology, many devices are planned to operate in the microwave frequency band (>1GHz) or even millimeter wave (30GHz) range. From this, it can be seen that the frequency is increasing, and the requirements for PCB boards are also high. For example, the substrate material needs to have high-quality electrical properties and chemical stability. With the increas

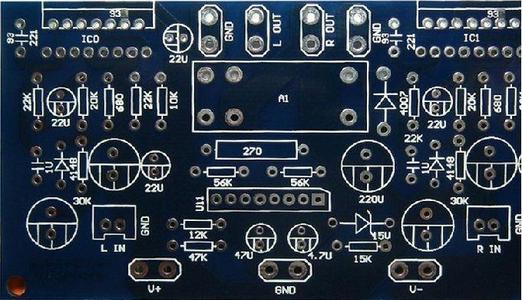

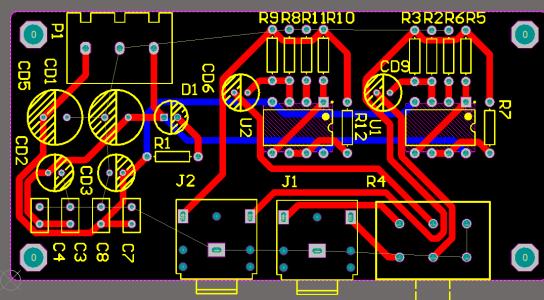

PCB design is a 'slow work leads to meticulous work' job, where everyone has their own set of solutions. Now let the engineer introduce to you what are the precautions for PCB design? 1. PCB design should have a reasonable direction For example, input/output, AC/ DC, strong/weak signal, high/low frequency, high/low voltage, etc. Their directions should be linear (or separate) and cannot merge with each other. Its purpose is to prevent mutual interference. 2. Choosing a Good Contact Position in PCB Design Usually, some commonality is required, such as the multiple grounding wires of the forward amplifier should converge and then be connected to the main line. In fact, due to various limitations, it is difficult to fully achieve this, but this principle should be followed as much as possible. 3. PCB design should correctly arrange capacitors Usually only a few power filters/decoupling capacitors are drawn, but it is not indicated where they should be placed. In fact, these cap

PCB circuit boards have many "layers", and many beginners are easily confused by various layers of PCB when learning PCB design. Below, let the engineer summarize the definitions of various layers in PCB circuit board design for you to help you better understand and master. 1. Mechanical layer Usually used to place indicative information about circuit boards and assembly methods, such as PCB dimensions, size markings, data, assembly instructions, and other information. 2. Occlusive layer Draw a closed area on this layer as the effective area for wiring, which cannot be automatically arranged and routed. 3. Silk screen layer The silk screen layer is a text layer that belongs to the top layer of a PCB and is typically used to mark the projected contour of components, their labels, nominal values or models, and various annotation characters. 4. Welding layer The solder entry layer is the green part of the printed circuit board. After mapping the shape of the welding layer onto

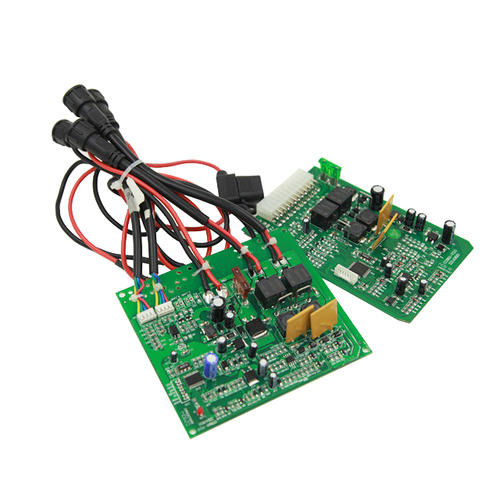

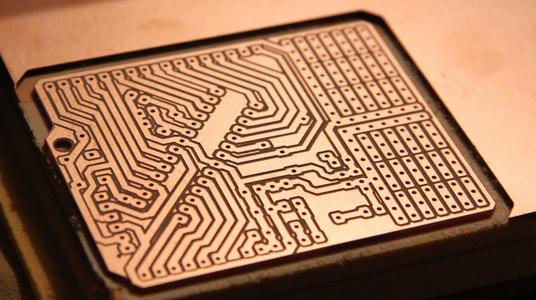

As a group of engineers, the sampling precautions include: 1. Carefully select the sample quantity to effectively control costs. 2. Special confirmation of device packaging to avoid sample failure due to packaging errors. 3. Conduct a global electrical inspection to improve the electrical performance of the PCB board. 4. Ensure signal integrity layout, reduce noise, and improve PCB stability. As a circuit board sampling manufacturer, the sampling precautions include: 1. Carefully check the PCB file information to avoid data issues. 2. Conduct global process approval and configure the process with our own manufacturers. 3. Control production quantity, reduce costs, and ensure quality. 4. Communicate precautions with sample customers to prevent accidents in advance.

The circuit board manufacturer reveals to you why the circuit board is deformed? The uneven copper surface area on the circuit board can worsen the bending and warping of the board. Nowadays, circuit boards are mostly multi-layer boards, and there are connection points (vias) between layers that are like rivets. The connection points are divided into through holes, blind holes, and buried holes. The places with connection points will limit the effect of board expansion and contraction, and indirectly cause board bending and warping. 1. Generally, circuit boards are designed with a large area of copper foil for grounding purposes. Sometimes, the Vcc layer also has a large area of copper foil. When these large areas of copper foil cannot be evenly distributed on the same circuit board, it will cause uneven heat absorption and dissipation speed. Of course, circuit boards will also expand and contract with heat. If the expansion and contraction cannot be achieved simultaneously, it wi

Circuit board sampling refers to the trial production of printed circuit boards before mass production. Generally, it refers to electronic products that are sent to PCB manufacturers for processing after being designed by engineers. The update and iteration of electronic products are relatively fast, so the demand for PCB sampling is gradually growing, and the market share is constantly expanding. With the increasing requirements for electronic product technology and information speed, the rise of multi-layer PCB sampling is relatively fast. 1. There are two ways to sample: formal PCB factories and specialized sample companies. It is more suitable to find a sampling company in your situation. They rely on sampling fees to survive and will definitely accept your request to only make two pieces. 2. The purpose of regular factory sampling is to have bulk orders, so of course, we hope to return orders; The sampling company itself only produces samples or small batches, and even if yo

1 Revenue Both high-frequency circuits and low-frequency power supply circuits have voltage gain and output power harvesting effects. Resonant differential amplification circuit refers to the resonant frequency f0, and for fiber broadband differential amplification circuit, it refers to a frequency range. 2-way band The concept difference with low-frequency power circuit boards is good. For resonant differential amplification circuits, most of them are the values between the two corresponding frequencies when the normalized vibration amplitude of the pointer decreases to 0.707 for the resonant frequency f0; For fiber optic broadband amplification circuits, it refers to the corresponding meaning relative to a certain frequency. 3. Selectivity Selectivity mainly targets resonant amplification circuits, which characterize the circuit's ability to select useful signals and suppress useless signals. Usually, the rectangular coefficient and suppression ratio are measured based on th

There are five main driving factors for the development of high-performance HDI circuit board products, which affect each other. The factors considered in this type of circuit design are: circuit components (signal integrity), sheet metal, stacking, and design standards. Although circuits are crucial for considering signal integrity, cost factors cannot be ignored. Based on this, it is important to consider a compromise solution during the operation process. The performance of the actual circuit varies with the rise time of the signal. These large area, high-performance HDI circuit boards handle high-speed computer buses or telecommunications signals, and are very sensitive to noise and signal reflection. The following five basic characteristics can describe signal sensitivity: characteristic impedance, low-voltage differential signal (LVDS), signal attenuation, noise sensitivity, and crosstalk interference. The characteristic impedance of single ended microstrip lines, stripline

Inquiry Now