+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

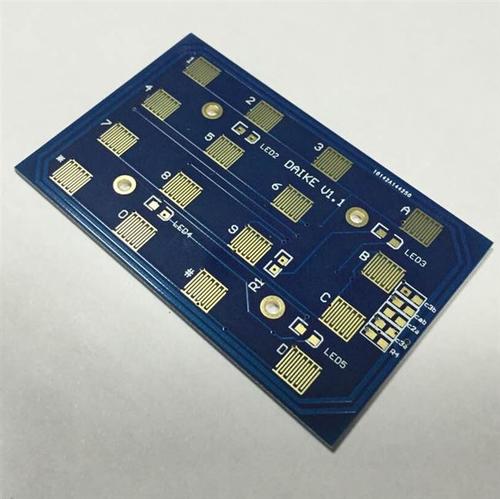

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

1. Report the results of the work The leader who lifts the heavy weight is the favorite. When reporting work, please remember to report the result to the leader first, and the result thinking is the first thinking. 2. Ask for work plan Please ensure that at least two programs are given to leaders, and express their views and effective suggestions. Don't let the leader do the quiz questions, but let the leader do the multiple-choice questions. Don't ask the leader how to do this thing, what to do, but ask, I have a plan, you can listen to it and see how it goes! 3. Summarize the work process and find three points To do a work summary, it is necessary to describe the process, not only to have a clear sequence and logic, but also to find out the key points, mistakes, and reflection points in the process. 4. Arrange work standards and clarify customer requirements Layout work must be clear about customer requirements and quality standards, otherwise subordinates will not know ho

1. Temperature of soldering iron SMT tends to work at a temperature equivalent to that of a hot soldering iron (approximately 375 ℃), making things faster and requiring fine-grained IC welding techniques to work below. The actual temperature setting will vary for different irons, but it may range from 330 ° C/626 ° F to 380 ° C/716 ° F (although some inexpensive temperature controlled soldering irons may not have accurate temperature settings if they do not work well, so try to be higher). Most modern components have a considerable amount of elasticity and are designed to handle automatic welding and lead-free solder, but even at these high temperatures, it is best not to leave contact with the iron for too long, 2. Solder 0805 chip resistors and capacitors Apply flux to both pads. Use tweezers and/or tips to achieve the position of the component. Load some solder onto the soldering iron head. At the same time, use a tip to keep the component in place, and touch the soldering

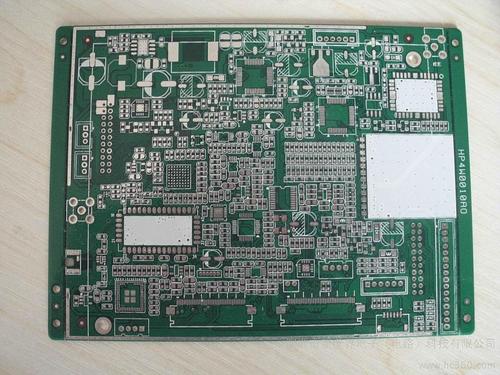

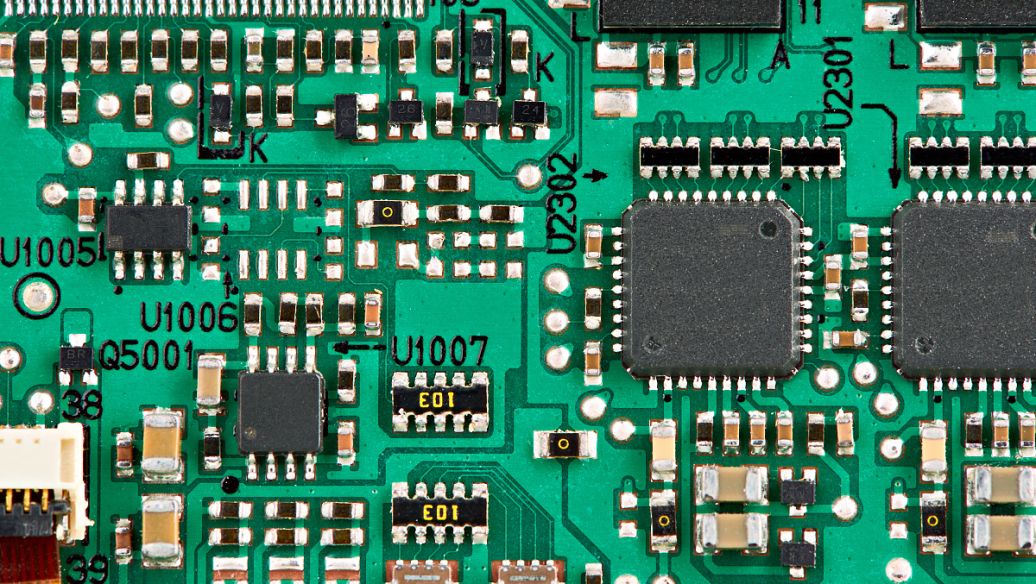

As a provider of electrical connections for electronic components, PCB is known as the "mother of electronic products". It is understood that each electronic product requires customized circuit boards, which means that no matter how the electronic industry's products are upgraded, there will be a continuous demand for circuit board copying. In addition to imitating and cloning existing circuit boards, PCB copying can also improve existing technology and accelerate the upgrading and upgrading of electronic products. Therefore, we can also say that the PCB copying industry is a very active industry in the electronic component industry. From the perspective of industry division, PCB copying is undoubtedly a segmented and special industry, and its industry characteristics determine that PCB copying enterprises have their own business characteristics. Currently, with electronic component products becoming increasingly miniaturized and complex, global PCB copying manufacturers are facing

1: Establish encapsulation that is not present in the encapsulation library. Before designing the PCB board sample diagram, if a certain component in the schematic diagram cannot find a packaging model in the packaging library, it is necessary to use the component packaging model editor to create a new one. It is necessary to ensure that the packaging model of the used component is complete in the packaging library (which can be multiple library files) to ensure the smooth progress of PCB design. 2: Set PCB board design parameters. According to the needs of circuit system design, set the number of layers, size, color, etc. of the PCB board. 3: Load network table. Load the network table generated from the schematic diagram and automatically load the component packaging model into the PCB design window. 4: Layout. A combination of automatic and manual layout methods can be used to place the component packaging model in an appropriate position within the PCB planning range, making

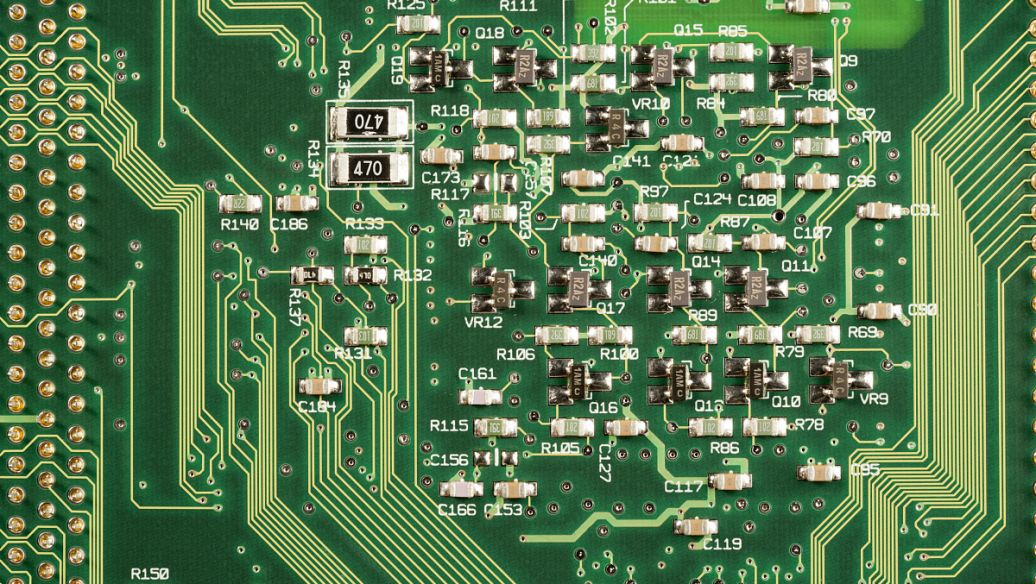

1: The distance from the edge of the circuit board is generally not less than 2MM. The shape of the circuit board is rectangular, and the aspect ratio is 3:2 or 4:3. When the surface size of the circuit board is greater than 200MM by 150MM, the mechanical strength that the circuit board can withstand should be considered. 2: In general, all components should be arranged on the same side of the circuit board. Only when the top layer components are too dense can some highly limited and low heat generating devices, such as SMD resistors, capacitors, ICs, etc., be placed on the lower layer. 3: The minimum spacing between adjacent solder pads of different components on the PCB sample circuit board should be at least 1MM. 4: On the premise of ensuring electrical performance, components should be placed on a grid and arranged parallel or perpendicular to each other, in order to be neat and beautiful. In general, components are not allowed to overlap; The arrangement of components shoul

Counting the busy people in 2012, there are indeed many. Du Fu is busy getting graffiti, Mr. Bao is busy clarifying his skin color, and Yuan Fang is busy answering questions and solving doubts. However, the busiest thing to say is the consumers who choose from countless electronic products. The electronics industry is fiercely competitive, and consumers are undoubtedly the biggest beneficiaries. Under the competition of electronic products, the electronic component industry has attracted much attention. When PCB copying breaks the traditional circuit board industry and embarks on a "non mainstream" path, colorful and exciting scenes will surely unfold one after another. Circuit boards are important electronic components and support electronic components. Circuit board copying (PCB copying) is a reverse research technique that can visualize the core technology of electronic products and absorb it into one's own technology. As a leading enterprise in the board copying industry, Xing

1. Function and Characteristics: Nickel plating is used as a substrate coating for precious and base metals on printed circuit boards (PCB), and is also commonly used as a surface layer for certain single-sided printed boards. The PCB sampling manufacturer tells you that for heavy load worn surfaces such as switch contacts, contact pads, or plug gold, using nickel as the gold substrate coating can greatly improve wear resistance. When used as a barrier layer, nickel can effectively prevent the diffusion between copper and other metals. The combination coating of matte nickel/gold is often used as a metal coating for corrosion resistance, and can meet the requirements of hot pressing welding and brazing. Only nickel can be used as a corrosion resistant coating with ammonia based etchants, and PCBs that do not require hot pressing welding and require a bright coating are usually coated with smooth nickel/gold. The thickness of nickel coating is generally not less than 2.5 microns, us

1. During the production process, loose materials may be generated due to equipment and other factors. Therefore, during the operation process, the operator should check the material step distance before pasting and when taking over the shift. Each time the garbage is poured, the throwing box and garbage bin should be checked to collect the loose materials. At the same time, excessive abnormal situations of loose materials should be reported to the line leader. 2. Classify the bulk materials according to the appearance of the components, and verify the back pattern of the components to determine the material code. Then, package the verified bulk materials in an anti-static bulk box or bag, and mark the material code with the signature of the confirming person. 3. The loose materials generated on duty should be loaded 1 hour before work or when there are still 100 pieces left on the task order. When the loose materials are online, the operator first checks the material code and ba

Inquiry Now