+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

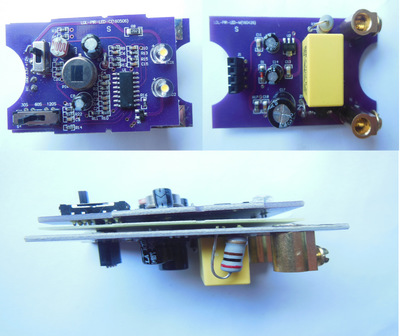

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

First of all, let's talk about the difference: through holes are drilled holes on PCBs, usually used for interlayer conductivity and also for heat dissipation. A pad is a pad on a via, just like a pad for inserting devices. But! In the production and manufacturing process of PCB circuit boards, their processing methods are different. 1. The number of holes indicated in the design of VIA is determined by drilling. Then there are also process steps such as copper deposition, and the actual pore size will be approximately 0.1mm smaller than the designed pore size. For example, if the through-hole is set to 0.5mm, the actual aperture after completion is only 0.4mm. 2. The aperture of PAD will increase by 0.15mm during drilling. After undergoing copper deposition process, the aperture is slightly larger than the designed aperture, about 0.05mm. For example, if the designed aperture is 0.5mm, the drilling will be 0.65mm, and the completed aperture will be 0.55mm. 3. VIA may be co

SMT processing is the most common technology in the SMT processing industry. What questions do we need to know about such a process? How can we comprehensively understand the technology of SMT processing? How can we comprehensively understand the factors that contribute to these problems? Here are a few points for you: 1: Placement of SMT processing: Its function is to accurately install surface mounted components onto the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. 2: Screen printing for SMT processing: Its function is to leak solder paste or SMT adhesive onto the PCB pad, preparing for the welding of components. The equipment used is a screen printing machine (screen printing machine), located at the forefront of the SMT production line. 3: Solidification of SMD processing: Its function is to melt the SMD adhesive, thereby firmly bonding the surface assembled components with the PC

The current management situation of small and medium-sized enterprises in China can be divided into three types: first, management without management; Secondly, there is management, but the form of expression is relatively extensive; The third is to have management, but it is not the crystallization of the natural development of one's own enterprise, but rather a product that is "borrowed" and basically belongs to the type of "copying and copying". 1. There is no "management" management, which means that enterprises do not have a fixed management model and rely solely on command and command to act. In this type of enterprise, there is no organizational structure, no clear division of labor, and often an employee has to hold multiple positions, with the element of human governance running through it. The management of the enterprise relies entirely on the consciousness of family relationships, and commands or commands fill the entire process of enterprise management. Usually, there

The exceptionally weak quality control and technical management in circuit board factories can lead to product quality problems. The quality department and technical department are important in circuit board enterprises, and most circuit board factories with abnormal quality have a common point, which is chaotic internal management. So, in order to improve product quality and reduce manufacturing costs, the circuit board sampling manufacturer tells you that the circuit board factory should have made improvements in the following aspects: 1. Everyone has responsibilities and everything has a process The circuit board factory should clarify the functions and job responsibilities of the technical and quality departments, especially for order review, product process drawings, FPC/PCB inspection standards, etc., to avoid the production and material departments from privately changing information. The biggest taboo in management is to rely on power for management. Circuit board factories

1、 PCB copying material Taking ordinary double-sided sheet metal as an example, sheet materials generally include FR-4, CEM-3, etc., with sheet thicknesses ranging from 0.6mm to 3.0mm, and copper thicknesses ranging from frac12oz to 3oz, all of which cause significant price differences in sheet metal; In terms of solder resist ink, there is also a certain price difference between ordinary thermosetting oil and photosensitive green oil. 2、 PCB board copying production process Different production processes can result in different costs, such as gilded and tinned plates, gongs (milled) and beers (punched) plates for manufacturing shapes, and the use of silk screen and dry film circuits. 3、 PCB copying difficulty Even if the materials and processes are the same, the difficulty of the PCB itself will result in different costs. If there are 1000 holes on both types of circuit boards, and one board has a hole diameter greater than 0.6mm and the other board has a hole diameter less t

In recent years, Pcb liquid medicine has gradually shifted from being environmentally friendly to being environmentally friendly. The government has increased its punishment efforts, and the industry and PCB manufacturers or suppliers have begun to pay close attention to environmental issues. Environmentally friendly chemical solutions emit less exhaust gas, wastewater, and waste, making them easy to handle, creating a friendly working environment, and providing more protection for workers' physical health. For example, in the field of porous metals, in recent years, more and more PCB companies have chosen organic conductive film direct electroplating. This metallization process does not emit formaldehyde gas, which not only greatly improves the working environment, but also has no complex wastewater and simple treatment methods, greatly saving water and electricity, and reducing operating costs. Wise individuals in the PCB industry have begun to call for innovation in the PCB sa

PCB circuit board impedance refers to the parameters of resistance and reactance, which hinder AC power. In the production of PCB circuit boards, impedance processing is essential. The reasons are as follows: 1. PCB circuits (bottom of the board) should consider the installation of electronic components by plugging, and after plugging, issues such as conductivity and signal transmission performance should be considered. Therefore, it is required that the impedance should be as low as possible, and the resistivity should be less than 1&TIMes per square centimeter; Below 10-6. 2. During the production process of PCB circuit boards, they need to go through processes such as copper deposition, electroplating tin (or chemical plating, or thermal spraying tin), and connector soldering. The materials used in these processes must ensure a low resistivity to ensure that the overall impedance of the circuit board meets product quality requirements and can operate normally. 3. The tin plat

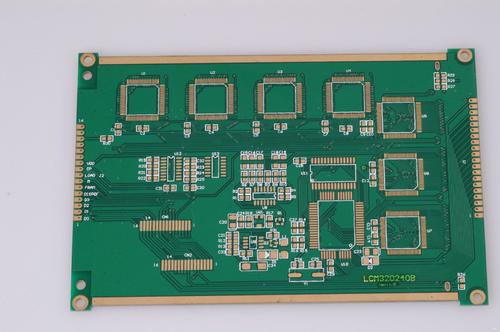

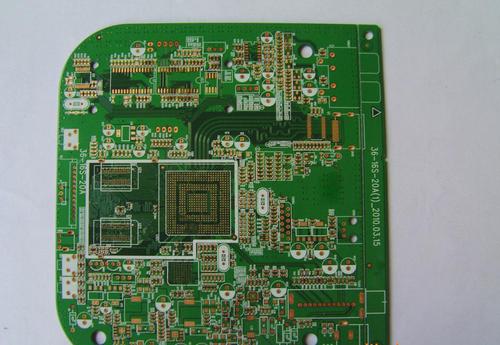

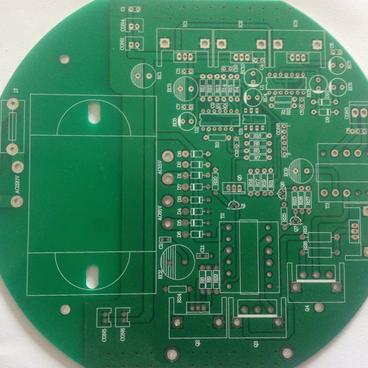

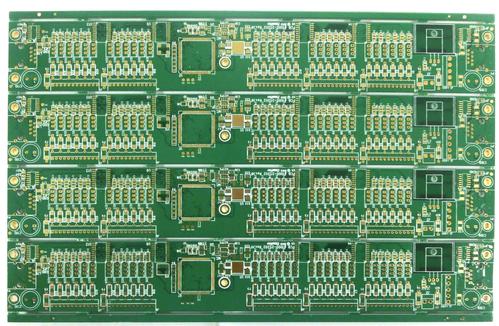

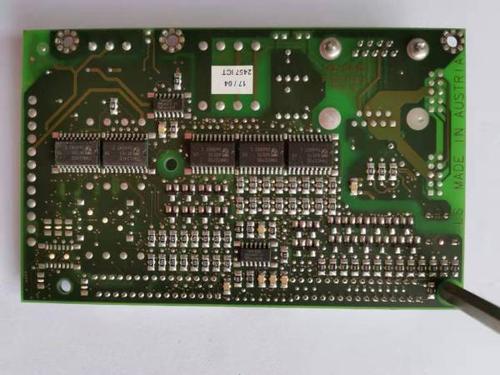

What is a circuit board Printed Circuit Board, commonly known as PCB, is a complex manufacturing process that involves dozens of processes such as inner layer, pressing, and drilling. It is generally classified according to the number of layers and characteristics, and can be divided into three types based on the number of layers: single-layer board, double-layer board, and multi-layer board. Single panel refers to a circuit board where wires are concentrated on one side, Double panel refers to a circuit board with wires distributed on both sides, while multi-layer single refers to a circuit board with more than two sides. Circuit board classification: 1. Flexible board 2. Rigid plate 3. Soft hard combination board Circuit boards can be divided into three main categories based on their characteristics: flexible boards, rigid boards, and soft hard composite boards. Flexible boards, also known as FPCs, are mainly made of flexible substrate materials such as polyester film, whic

Inquiry Now