+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

Firstly, it has a high degree of automation and can achieve fully automated bending and bending processes, reducing the possibility of manual intervention and improving production efficiency and quality. Secondly, the mobile FPC bending machine adopts advanced control systems and sensor technology, which can monitor and adjust the bending angle and force in real-time, ensuring that each FPC can meet the design requirements. In addition, the mobile FPC bending machine also has flexibility and adjustability, which can adapt to the bending needs of different models and sizes of FPC. To summarize, mobile phone FPC bending machines play an important role in mobile phone production. It can achieve high-precision bending and bending, improve production efficiency and quality, and has flexibility and adjustability. With the continuous innovation and development of mobile phone exterior design, mobile phone FPC bending machines will continue to play an important role in providing better

Poor development of PCB circuit boards has always been a common problem faced by manufacturers and the manufacturing industry. With the continuous development and complexity of electronic devices, the requirements for circuit boards have become increasingly high. The problem of unclear development on the circuit board not only affects the quality and performance of the product, but also may lead to functional failure of the product. It is very important to understand the reasons for unclear development and find solutions. 1. Developer contamination: Developer is an indispensable part of the development process of circuit boards, which can remove uncured photosensitive adhesive. However, if the developer is contaminated, such as the presence of precipitates, metal particles, or other impurities, it can lead to unclean development. Solution: Regularly replace the developer and ensure that its quality and purity meet the requirements. At the same time, before using the developer, it

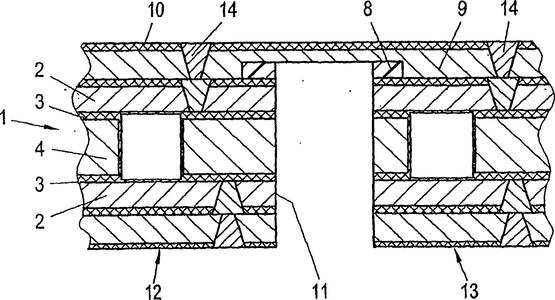

The traditional COF FPC used in the television industry is not much different from ordinary FPC in the production and processing process. In addition to the finer line width and spacing compared to ordinary FPC, FPC is still produced using standard reduction etching method. The COF FPC carrier board used in smartphones is produced using a completely different method from the standard subtractive etching method, using an additive method for semiconductor chips. The industry calls this process the SAP semi additive method. Because the minimum line width and line spacing of FPC produced by standard reduction etching method are generally above 15 microns, it is basically powerless for COF production processes with finer lines. The processing technology of SAP semi additive method mainly comes from SLP type carrier PCB. However, when it entered the smartphone industry, Apple was the first to use this technology on a large scale in the production of mobile phone motherboards. Earlier, w

At present, there are approximately 1500 PCB enterprises in China, forming a pattern of joint competition among Taiwanese, Hong Kong, American, Japanese, and domestic enterprises. Among them, foreign-funded enterprises generally have a large investment scale, and have certain advantages in production technology and product specialization; There are many domestic enterprises, but there is still a certain gap in their scale and technological level compared to foreign enterprises. Among them, China's printed circuit industry is mainly distributed in the southeast coastal areas, which is also related to the large demand for water in the PCB industry. These areas are relatively rich in water resources. The Yangtze River Delta and the the Pearl River Delta add up to 90% of the national total. The PCB industry investment analysis indicates that the ratio of the Yangtze River Delta to the Pearl River Delta is about 1:1 at present. The proportion of boards (single panel, double-sided boar

In the era of low profit in electronic products, price wars have changed the supply chain. The total output value of China's PCB industry reached 58.84 billion yuan, an increase of 8.6% year-on-year, with an average compound growth rate of 20% in revenue and a compound growth rate of 27% in net profit attributable to the parent company. The following is an analysis of investment in the PCB industry. Due to the concentration of downstream industries and relatively low labor and land costs, China has become the region with the strongest development momentum. In 2017, China surpassed the United States for the first time and became the world's second largest PCB producer. The proportion of output value also increased from 8.54% in 2000 to 15.30%, nearly doubling. As of 2018, the newly planned investment in China's PCB industry reached 95.5 billion yuan, with 72 new investment projects, with an average investment of 1.3 billion yuan per project. The newly planned investment amounts fo

1. Resistor: One of the common components in a circuit. Its main function is to limit the flow of current and control the voltage and current levels in the circuit. By adjusting the circuit signal with different resistance values, it is possible to prevent overcurrent from damaging other components. 2. Capacitor: A common component in a circuit that stores energy. Capacitors can store and release charges under the action of an electric field. It plays a storage and discharge role in the circuit, used for circuit functions such as filtering, coupling, and voltage stabilization. 3. Diode: A nonlinear component in a circuit. Diodes have a single conductivity and can only circulate current in one direction. It is commonly used for circuit rectification, current limiting, and protection functions. 4. Transistor: An important semiconductor device in electronic equipment. The transistor can amplify current and voltage signals, and has various functions such as switching, amplification, a

There are significant differences in usage between rigid circuit boards and flexible circuit boards. Rigid circuit boards are suitable for scenarios with high requirements for stability and reliability, while flexible circuit boards are suitable for scenarios with high requirements for shape and weight. Rigid circuit boards have a fixed shape and size, which can provide good stability and mechanical strength, making them suitable for most general electronic devices. Flexible circuit boards can be bent and folded according to design requirements, with strong shape variability, making them suitable for products with special shapes and lightweight designs. With the continuous development and innovation of electronic products, the application prospects of rigid circuit boards and flexible circuit boards in different fields are becoming increasingly broad. Rigid circuit boards still dominate traditional large electronic devices, but the application of flexible circuit boards in wearabl

FPC: Flexible Printed Circuit, abbreviated as Flexible Board, in English. It is a single-sided, double-sided, and multi-layer circuit board made by using an etching process on a flexible substrate surface. The surface circuit can also be electrically connected to the inner and outer layers through metallized holes. The production method of flexible circuit boards is simple and cost-effective, while compared to traditional (hard boards), they achieve weight breakthroughs and are thinner. Flexible circuit boards in certain fields can also effectively reduce device volume and facilitate portability. It has a wide range of application scenarios, high experimental value, and long-lasting research and preparation enthusiasm. So far, the vast majority of FPC board circuit fabrication has been done using addition and subtraction (etching) processing, usually by photolithography on copper foil to prepare traditional FPC boards. Firstly, the printing/lithography circuit needs to be printed

Inquiry Now