+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

Have you noticed that now more and more of our lighting is using led lighting.What is LED? Compared to the traditional light bulbs, LEDs have lower power consumption, longer lifetime and higher energy efficiency. In the PCB industry,when we say LED PCB, it refers to the pcb used for LED lighting, if you are looking for a suitable LED PCB for your lighting system, this article may bring you something. WHAT ARE LEDS COMPOSED OF?LED is an initial light-emitting diode that produces light when an electric current passes through. LEDs typically have negative and positive electrodes, which generate light in the visible light region.The LEDS are glued to the PCB by soldering process and have electrical connections for lighting.Since light-emitting diodes dissipate a lot of heat when they are in use, when you are designing LED, the metal core is usually the best choice for LED PCB, it is because that it dissipates heat more faster. Among them, the metal material aluminum is the most widely used

Printed circuit board manufacturing industry more and more need high aspect ratio, small hole printed circuit board plating process. It is the driving force to promote the development of high-level multi-layer printed circuit board manufacturing technology. Because of the reliability of the hole coating, it plays a key role in the use of printed circuit boards. How to ensure the problem of high aspect ratio deep hole plating is the scientific and technological task of all printed circuit workers, and it is the most important problem that must be faced. To this end, many research departments began to carry out planned research and development. There are many methods reported from the current scientific and technological data, including pulse plating technology, chemical vapor deposition technology, solution impact plating technology, full electroless copper plating technology and improved (high acid and low copper) air stirring technology. This part of the technology is introduced a

1, in the case of mastering the operation technology of the digital programming instrument, first load the film and the drilling test plate, measure the length and width of the two deformation, in the digital programming instrument according to the size of the deformation of the hole to lengthen or shorten the hole, with the drilling test plate after lengthening or shortening the hole to match the deformed film, eliminating the tedious work of splicing the film, to ensure the integrity and accuracy of the graph. This method is called "changing hole position method". 2, in view of the physical phenomenon that the negative changes with the change of ambient temperature and humidity, the negative in the sealed bag is taken out before the copy of the negative, and the working environment conditions are hung for 4-8 hours, so that the negative is deformed before the copy, so that the deformation of the negative after the copy is very small, called this method "hanging method". 3. For

1. Splicing method: Applicable: The line is not too dense, the film deformation of each layer is inconsistent; It is especially suitable for the deformation of solder resistance plate and multilayer plate power formation plate. Not applicable: film with high wire density, line width and spacing less than 0.2mm; Note: When splicing, the wire should be damaged as little as possible, and the welding pad should not be damaged. When splicing copy after revision, attention should be paid to the correctness of the connection relationship. 2, change the hole position method: Application: All layers of film deformation is consistent. This method also applies to film with dense lines; Not applicable: film deformation is not uniform, local deformation is particularly serious. Note: After using the programmer to lengthen or shorten the hole position, the out-of-tolerance hole position should be reset. 3, hanging method: Applicable; Film that has not been deformed and is protected from

1, engineering production -- light painting machine, film exposure machine 2, opening - opening machine, baking plate oven 3, laminating - brown production line, laminating machine, grinding machine 4, drilling -- CNC drilling machine 5, grinding board -- grinding machine 6, Metallized hole (PTH)-- chemical copper production line (copper wire) 7, graphics transfer - film machine, UV exposure machine or LDI 8, graphic plating - plating production line 9, dry (wet) film - film production line 10, graphic etching ---- etching production line 11, welding resistance layer production -- screen printing machine, UV exposure machine or LDI 12, baking and curing ---- oven, tunnel oven 13, surface treatment --OSP production line or chemical nickel gold line, chemical nickel palladium gold line 14, molding -- punching machine or CNC gong machine, cutting machine 15. Test -- Electric Measuring machine, AOI, 3DAOI. 4, the plate is scratched during the transfer process: a, the ha

1, hot air smoothing (spray tin) Hot air smoothing, also known as hot air solder smoothing (commonly known as spray tin), it is the process of coating molten tin (lead) solder on the surface of the PCB and heating compressed air to smooth (blow), so that it forms a coating layer that is resistant to copper oxidation and can provide good solderability. During hot air conditioning, a copper-tin metal intermetallic compound is formed at the joint of solder and copper. PCB for hot air finishing usually to sink in the molten solder; The air knife blows out the liquid solder before it solidifies; The air knife minimizes the meniscus of solder on the copper surface and prevents solder bridging. 2, organic weldability protectant (OSP) OSP is a process for printed circuit board (PCB) copper foil surface treatment in accordance with the requirements of the RoHS directive. OSP is short for Organic Solderability Preservatives, also known as organic solderability preservatives, also known as

Improvement method: 1, the copper clad plate in the warehouse before IQC must be random inspection, check whether the surface of the board scratches the substrate phenomenon, if there should be timely contact with the supplier, according to the actual situation, make appropriate treatment. 2, the copper clad plate is scratched during the opening process, the main reason is that there are hard objects on the surface of the opening machine, and the friction between the copper clad plate and the objects causes the copper foil scratch to form the phenomenon of exposing the substrate, so the table must be carefully cleaned before the opening of the material to ensure that the table is smooth and there is no hard objects. 3, the copper clad plate is scratched by the drill when drilling, the main reason is that the spindle clip is worn, or the debris in the clip is not clean, the drill is not firmly grasped, the drill does not go to the top, the length of the drill is slightly longer t

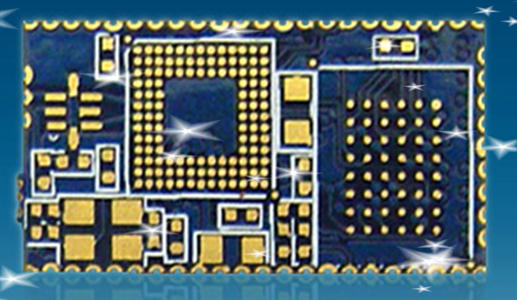

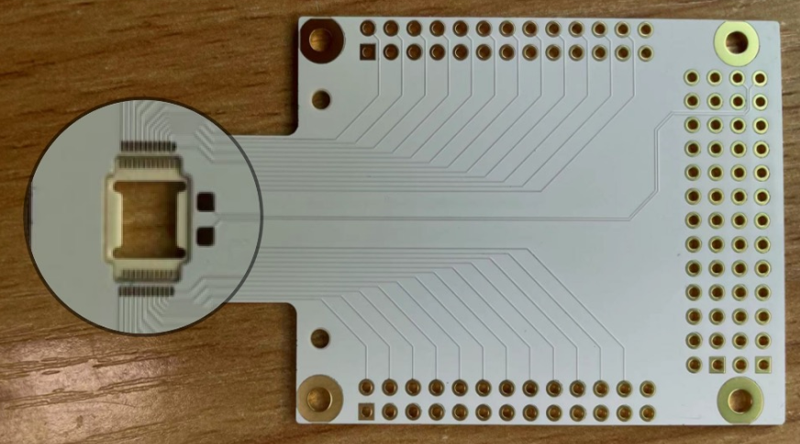

RO4000 Laminates RO4350B Cavity Opening BoardRo4350B material, cavity opening at L1-L2&L6-L5, 4mil bonding pad.Details: Cavity from Top Layer to L2. L2 has exposed pads with ENEPlG Plating for Wire Bonding.Cavity from Bottom Layer to L5. L5 has exposed pads with ENEPIG Plating for Wire Bonding.The 2 cavities are symmetric with each other.

PCB ink is mainly divided into three lines, solder resistance, character ink three categories. The line ink is used as a barrier layer to prevent corrosion of the line, and the line is protected when etched, which is generally liquid sensitive type. There are two kinds of acid corrosion resistance and alkaline corrosion resistance, alkali resistance is more expensive, this layer of ink should be dissolved with alkali after corrosion of the line. Solder resistance ink is applied to the line after the line is done to protect the line. There are liquid photosensitive and heat curing, as well as ultraviolet hardening type, the pad is retained on the board, which is convenient for welding components and plays the role of insulation and oxidation prevention. Character ink is used to mark the surface of the board, such as marking the component symbol, which is generally white. In fact, there are other inks, such as: strippable adhesive ink, which is to protect the part that does not nee

Inquiry Now