+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

PCB requires precision and attention to detail,contact us for a one-stop solution

Get your instant priceThick copper/Heavy copper boards Features and Applications

| Thick copper/Heavy copper boards |  |

|---|---|

Features Applications | Thick Copper / Heavy Copper PCBs

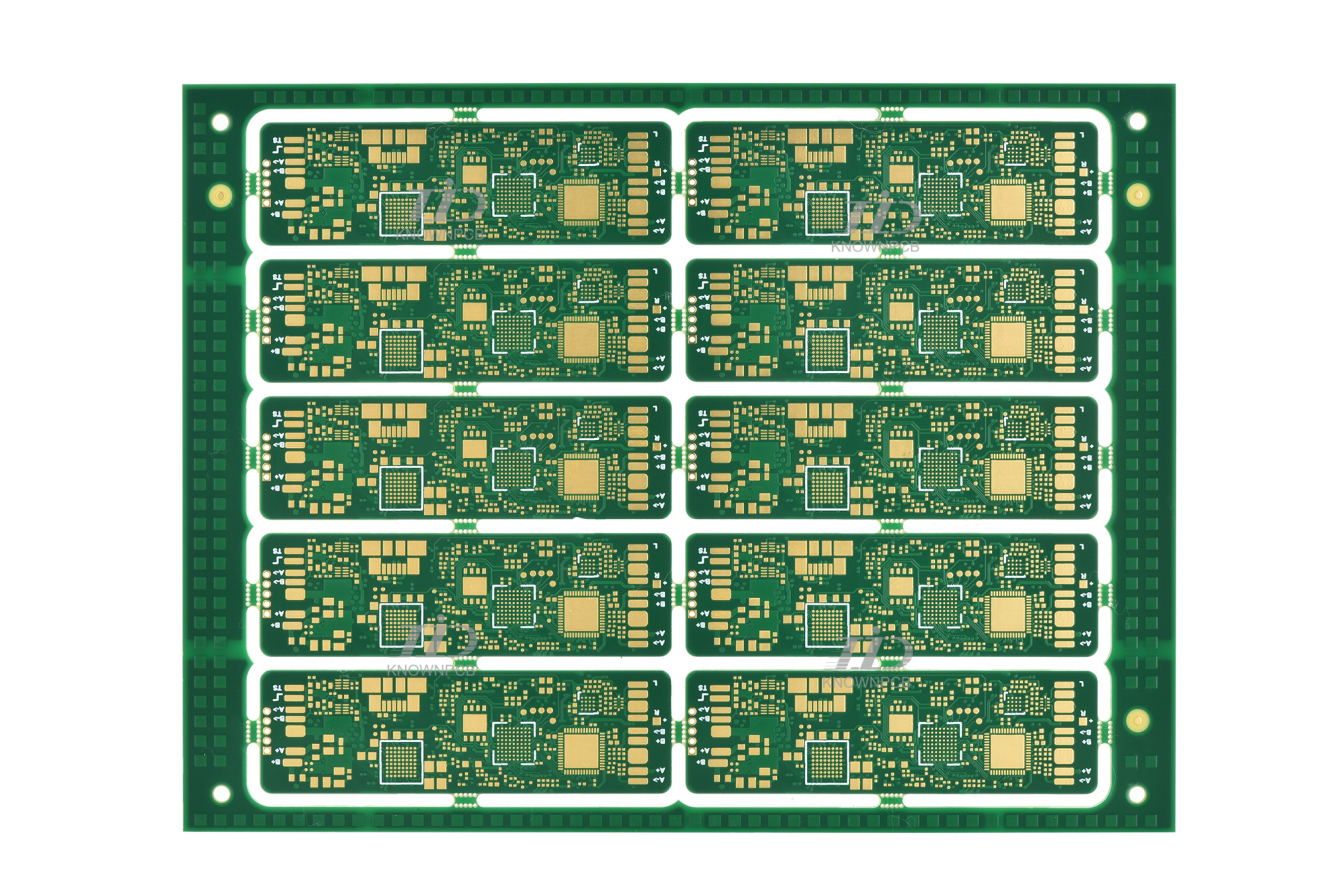

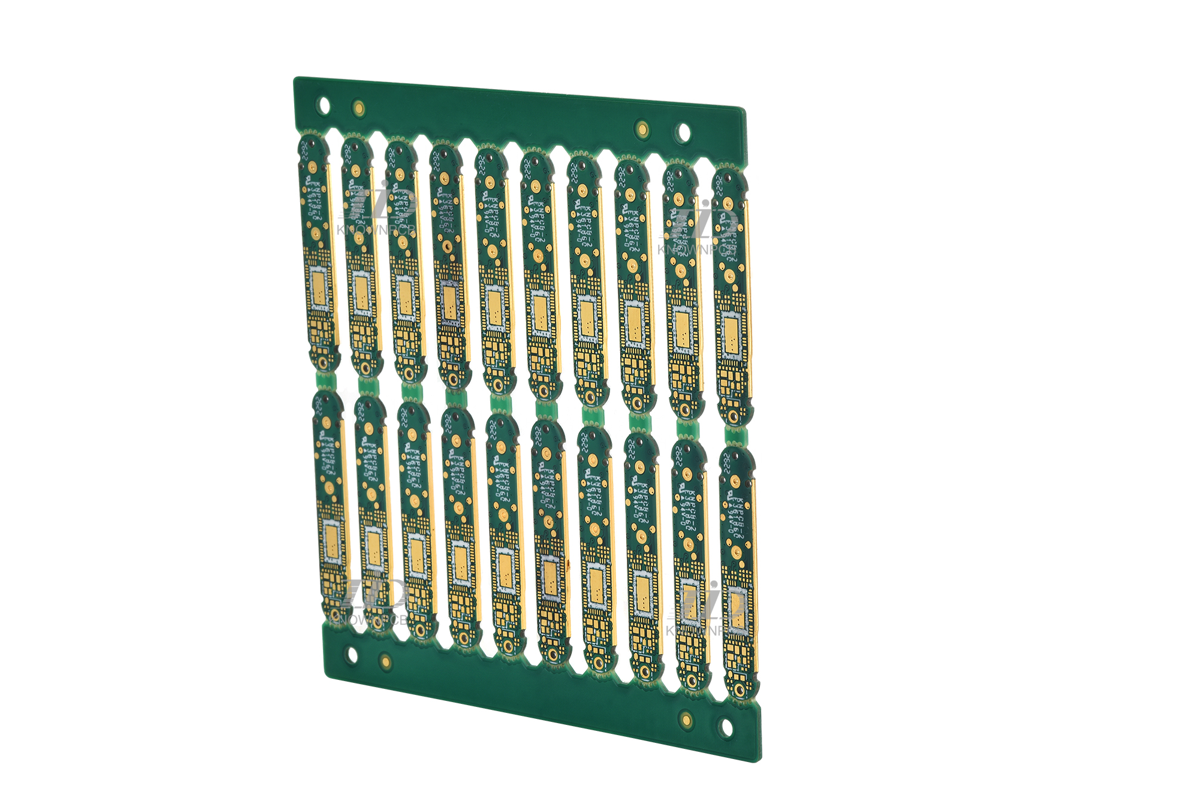

Thick copper or heavy copper PCBs refer to printed circuit boards that have copper layers thicker than the standard copper thickness used in regular PCBs.

Features of Thick Copper PCBs

1. Increased Copper Thickness: - Definition: Typically, PCBs with copper thickness greater than 2 oz/ft² (70 µm) are considered thick copper PCBs. Heavy copper PCBs can have copper thickness ranging from 3 oz/ft² (105 µm) up to 20 oz/ft² (700 µm) or even higher. - Enhanced Current Carrying Capacity: Thicker copper allows for higher current-carrying capabilities, reducing conductor resistance and enabling better thermal management. 2. Layer Structure: - Internal Layers: Copper layers within the PCB stack-up are thicker than standard PCBs, providing robust electrical and thermal performance. - External Layers: The external copper layers facilitate efficient heat dissipation and can handle increased mechanical stress. 3. Improved Reliability: - Durability: Thick copper PCBs offer increased mechanical strength and resistance to thermal cycling and mechanical stress, improving the board’s overall reliability. - Longevity: Enhanced copper thickness contributes to longer operational lifespans, crucial in high-reliability applications.

Applications of Thick Copper PCBs

1. Power Electronics: - Power Supplies: Used in high-power applications such as power supplies, inverters, and converters where high current loads and efficient heat dissipation are critical. - Motor Controllers: Employed in motor control applications requiring robust electrical connections and thermal management. 2. Automotive Electronics: - Battery Management Systems: Used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) for battery management and power distribution due to their high current handling capabilities. - Engine Controls: Applied in automotive engine controls and transmission systems where reliability under harsh conditions is essential. 3. Industrial Equipment: - Industrial Controls: Utilized in industrial automation and control systems, providing reliable performance in demanding environments. - Heavy Machinery: Used in heavy machinery and equipment where PCBs are subjected to high mechanical stresses and thermal loads. 4. Aerospace and Defense: - Avionics: Applied in avionics systems for aircraft communication, navigation, and monitoring, ensuring stable operation under extreme condition - Military Electronics: Used in military applications for ruggedized PCB requirements and high reliability in mission-critical systems.

Thick copper or heavy copper PCBs are specialized circuit boards designed to handle high current loads, improve thermal management, and enhance overall reliability in demanding applications such as power electronics, automotive systems, industrial equipment, and aerospace. Their increased copper thickness provides superior electrical conductivity and durability, making them essential for applications requiring robust performance and longevity. Contact us for more information or assistance with your thick copper PCB requirements.(We have more than 15 years of production and overseas PCB experience) |

Inquiry Now