+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

PCB requires precision and attention to detail,contact us for a one-stop solution

Get your instant priceRigid-flex PCB Features and Applications

| Rigid-flex PCB |  |

|---|---|

Features Applications | Rigid-Flex PCBs

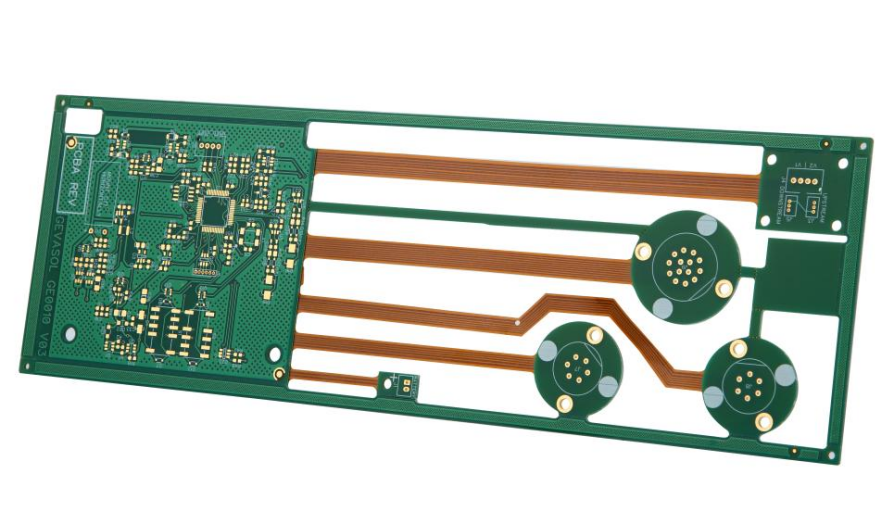

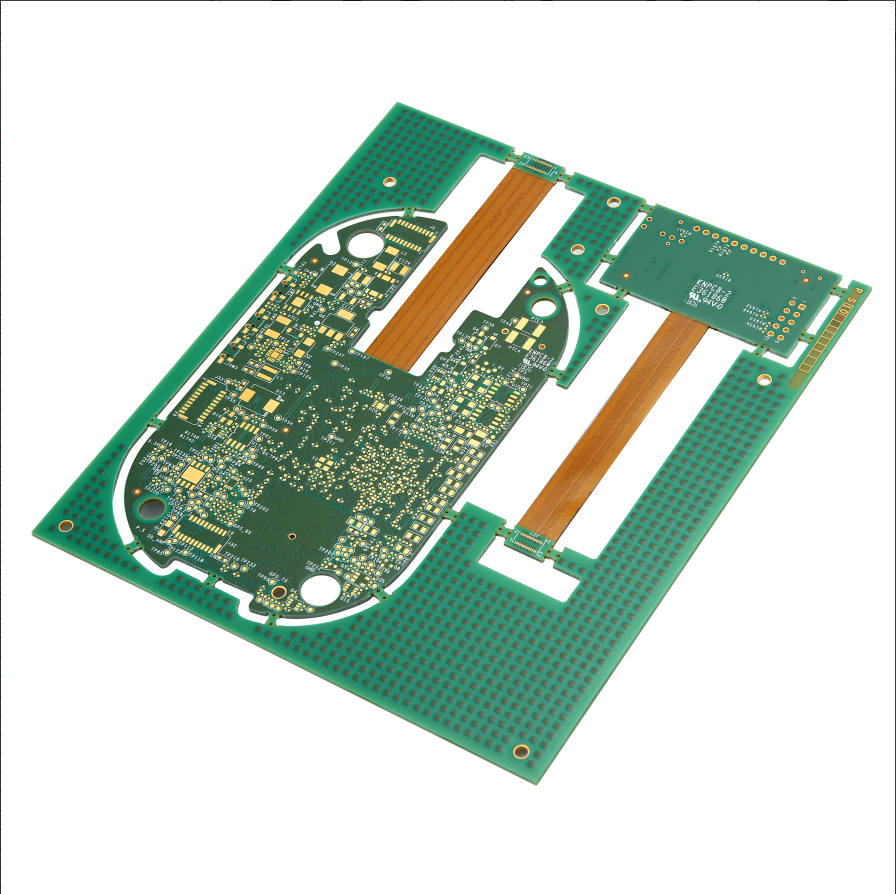

Rigid-flex PCBs combine the best features of both rigid and flexible circuits into a single board, offering numerous advantages for complex electronic applications. Rigid-Flex PCBs consist of multiple layers of rigid and flexible substrates laminated together into a single structure.

Features of Rigid-Flex PCBs

1. Combined Structure: - Rigid Sections: Provide structural integrity and support for heavy components. - Flexible Sections: Allow for flexibility and dynamic bending, suitable for complex shapes and constrained spaces. 2. Layer Configuration: - Multilayer Design: Typically involve multiple layers of rigid and flexible materials, interconnected through plated through-holes (PTHs) or microvias. - Complex Stack-Up: Combination of flexible and rigid layers requires careful planning of the stack-up to ensure signal integrity and mechanical stability. 3. Improved Reliability: - Reduced Interconnections: Fewer interconnects and solder joints between rigid and flexible parts reduce potential points of failure. - Dynamic Flexing: Capable of enduring dynamic flexing, making them suitable for applications requiring repeated bending. 4. Space and Weight Savings: - Compact Design: Integration of rigid and flexible circuits into a single board saves space and reduces weight, essential for portable and compact devices. - Three-Dimensional Assembly: Allows for three-dimensional assembly, optimizing the use of available space.

Applications of Rigid-Flex PCBs

1. Consumer Electronics: - Wearable Devices: Used in smartwatches, fitness trackers, and other wearable tech where space is limited and flexibility is required. - Mobile Devices: Applied in smartphones and tablets for compact design and reliability under mechanical stress. 2. Medical Devices: - Diagnostic Equipment: Essential for compact and reliable diagnostic tools and imaging systems. - Implantable Devices: Used in implantable medical devices where flexibility and reliability are critical. 3. Automotive Electronics: - Infotainment Systems: Used in car infotainment systems requiring reliable connections in a compact space. - Advanced Driver Assistance Systems (ADAS): Applied in ADAS for robust performance under varying mechanical conditions. 4. Aerospace and Defense: - Avionics: Critical for avionics systems where space constraints and reliability are paramount. - Military Equipment: Used in military applications requiring durable and lightweight circuitry. 5. Industrial Applications: - Robotics: Applied in robotic systems where flexibility and compact design are needed. - Industrial Control Systems: Used in control systems that require reliable connections in harsh environments.

Rigid-flex PCBs offer a versatile solution by combining the advantages of both rigid and flexible circuits. Rigid-flex PCBs are ideal for applications requiring compact design, mechanical flexibility, and high reliability, such as consumer electronics, medical devices, automotive systems, aerospace, defense, and industrial applications. Contact us for expert assistance and a one-stop solution for your rigid-flex PCB needs.(We have more than 15 years of production and overseas PCB experience) |

Inquiry Now