+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

PCB requires precision and attention to detail,contact us for a one-stop solution

Get your instant priceMetal Core PCBs Features, Applications

| Metal Core PCB |  |

|---|---|

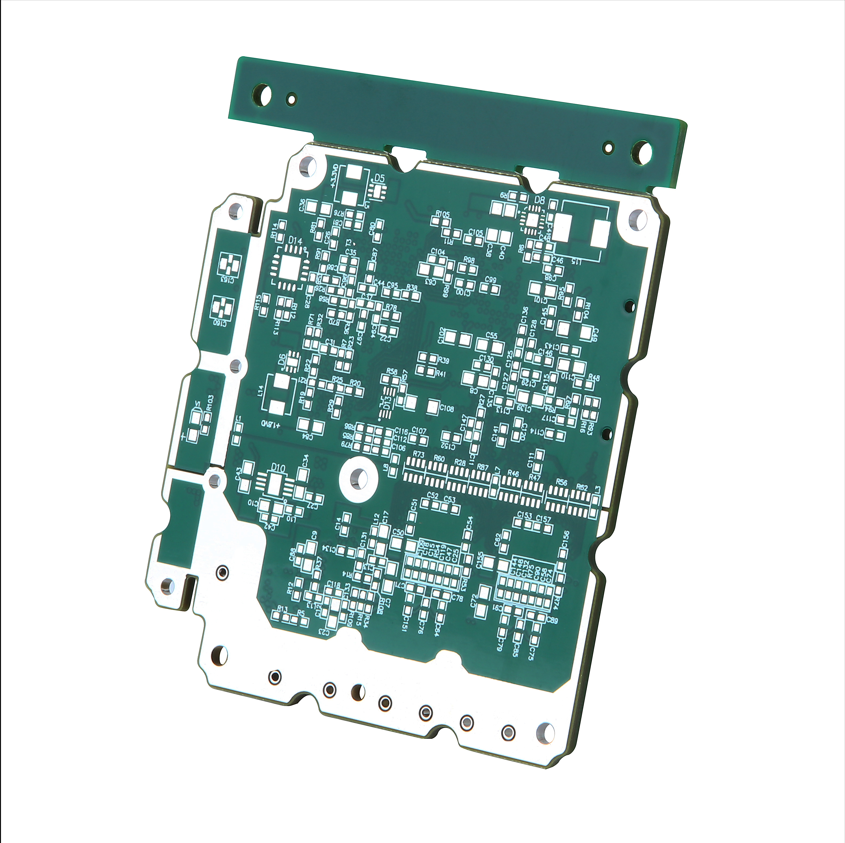

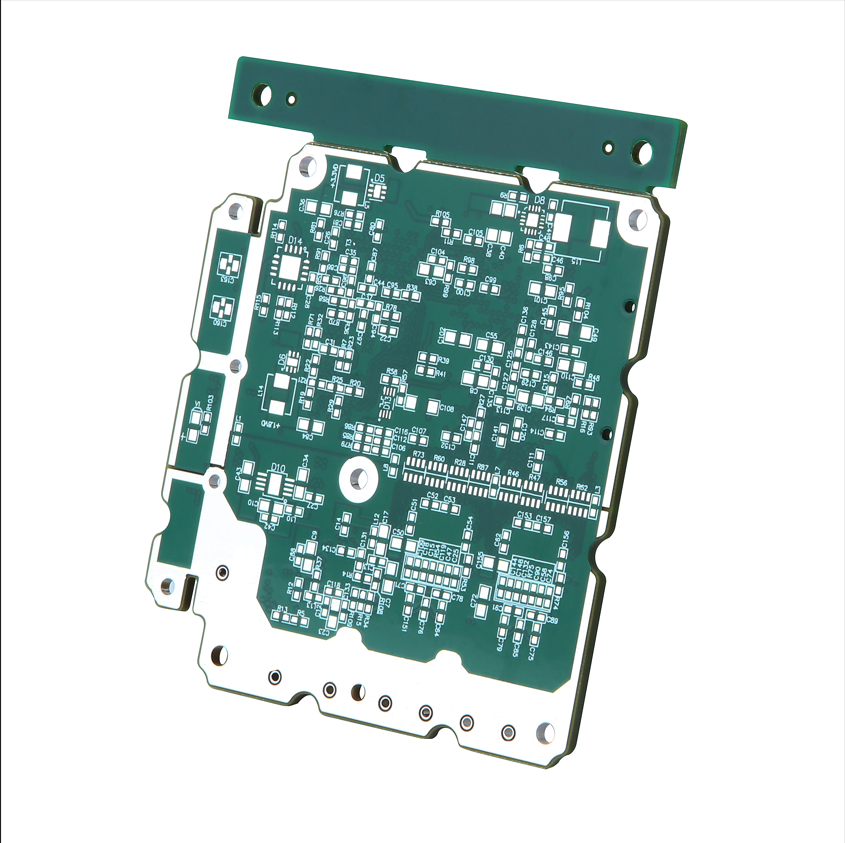

Features Applications | Metal Core PCB (MCPCB)

A Metal Core Printed Circuit Board (MCPCB), also known as a thermal PCB or metal-backed PCB, is a type of PCB designed to enhance thermal management by using a metal substrate.

Features of Metal Core PCBs

1. Metal Core Substrate: - Material: The core is typically made of aluminum, copper, or a mixture of special alloys. - Thermal Conductivity: The metal core provides excellent thermal conductivity, allowing for efficient heat dissipation away from heat-generating components. 2. Layer Structure: - Top Layer: The top layer consists of a thin layer of copper circuitry, similar to standard PCBs. - Insulating Layer: A dielectric layer lies between the metal core and the copper circuitry to provide electrical insulation while maintaining good thermal conductivity. - Metal Core: The metal core acts as the primary heat sink, absorbing and dissipating heat. 3. Enhanced Thermal Performance: - Heat Dissipation: MCPCBs are designed to handle high levels of heat, making them ideal for applications with significant thermal output. - Reduced Thermal Stress: By efficiently dissipating heat, MCPCBs reduce thermal stress on electronic components, enhancing their reliability and lifespan.

Applications of Metal Core PCBs

1. LED Lighting: - High-Power LEDs: MCPCBs are commonly used in high-power LED applications where efficient heat dissipation is critical to maintaining LED performance and longevity. 2. Power Converters: - Power Supplies: MCPCBs are used in power supplies and converters that generate substantial heat, ensuring stable operation and preventing overheating. 3. Automotive Electronics: - Headlights and Brake Lights: MCPCBs are used in automotive lighting systems, including headlights and brake lights, which require robust thermal management. 4. Solar Panels: - Solar Inverters: MCPCBs are employed in solar power systems, particularly in solar inverters, to manage heat generated during energy conversion. 5. Industrial Applications: - Motor Controllers: MCPCBs are used in industrial motor controllers and high-power machinery to ensure reliable operation under high thermal loads.

Metal Core PCBs (MCPCBs) are specialized PCBs designed for efficient thermal management, making them ideal for applications with high heat generation such as LED lighting, power converters, automotive electronics, solar panels, and industrial equipment. Contact us for a one-stop solution for your MCPCB needs.(We have more than 15 years of production and overseas PCB experience) |

Inquiry Now