+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2025-04-19

2025-04-19

873

873

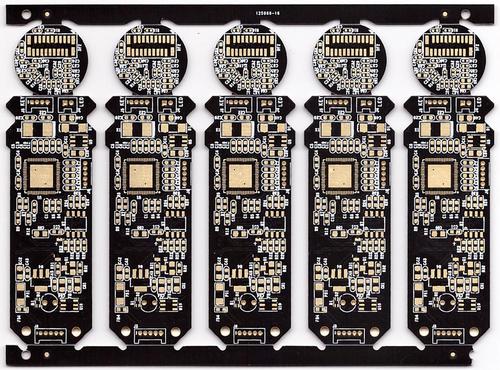

In the era of 5G technology, 5G PCB (Printed Circuit Board) boards play a pivotal role in ensuring the seamless operation of high - speed communication devices. These boards are the unsung heroes behind the functionality of 5G smartphones, base stations, and other related equipment.

Design and Complexity

5G PCB boards are engineered with a high degree of complexity. They need to accommodate a large number of components, including high - frequency chips, filters, and connectors. The design must consider factors such as signal integrity, impedance matching, and electromagnetic interference (EMI). To meet the high - speed data transmission requirements of 5G, PCB manufacturers use advanced design techniques. For example, they often employ multi - layer designs, which can stack multiple conductive layers separated by insulating materials. This allows for a more compact layout and better management of complex circuits.

High - Frequency Performance

One of the most critical aspects of 5G PCB boards is their high - frequency performance. 5G operates on a wide range of frequency bands, including millimeter - wave frequencies. At these high frequencies, the electrical properties of the PCB material become crucial. Specialized materials with low dielectric loss are used to minimize signal attenuation. This ensures that the signals can travel efficiently through the board without significant degradation, which is essential for maintaining high - speed data transfer rates and reliable communication.

Thermal Management

The high - power components on 5G PCB boards generate a significant amount of heat. Effective thermal management is, therefore, a must. PCB designers incorporate heat - sinking techniques, such as using copper planes with high thermal conductivity to dissipate heat. Some advanced 5G PCB boards also use thermal vias, which are small holes filled with a thermally conductive material to transfer heat from the inner layers to the outer layers for better dissipation.

Manufacturing Challenges

Producing 5G PCB boards comes with several manufacturing challenges. The high - precision requirements for drilling, plating, and etching demand state - of - the - art manufacturing equipment and strict quality control. Any small deviation in the manufacturing process can lead to performance issues in the final product. Additionally, as the demand for 5G devices continues to grow, manufacturers need to scale up production while maintaining consistent quality.

In conclusion, 5G PCB boards are at the heart of 5G technology. Their advanced design, high - frequency performance, thermal management, and the challenges in manufacturing all contribute to making them a key enabler of the 5G revolution. As 5G technology continues to evolve, we can expect further advancements in PCB board technology to meet the ever - increasing demands of high - speed communication.

Or call +86 755 2794 4155

Inquiry Now