+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2025-02-28

2025-02-28

311

311

FPCB, also known as FPC, full name Flexible Printed Circuit Board. These boards play a crucial role in modern electronics, and their functionality can be further enhanced or customized depending on the number of layers and the combination of rigid and flexible components. Here are the common types you need to know.

•Single Layer FPC

Lightweight and thin, suitable for consumer electronics.

•Double Layer FPC

Signal transmission capability greater than single-layer FPC in the same volume.

•Multi layer FPC

Multiply the number of high-precision circuits that can be loaded per unit area by stacking layers, which has the advantage of single-layer FPC.

•Rigid-flexible board

Higher performance and stability compared to normal products, while also limiting the scope of the design to a single component and optimising the available space.

About Structure of FPC

Now that we've explored the various types of FPC, it's time to dissect their structures. The structure of an FPC is the key to its performance and functionality.

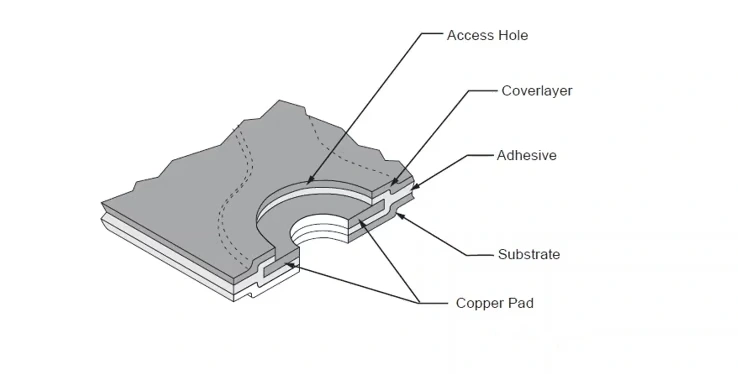

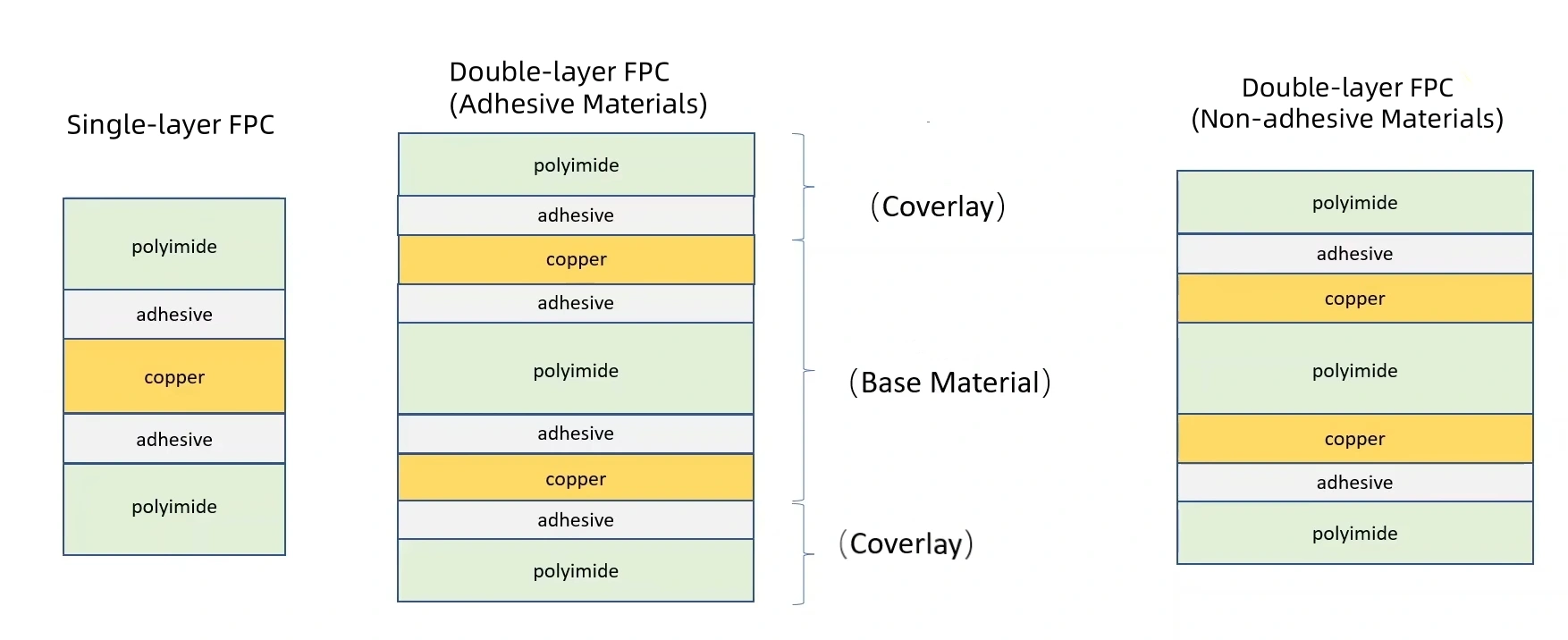

•Single-Layer FPC Structure

The substrate and cover layers are made from the same material, with a copper foil layer on each side of the substrate. The copper foil and cover layers are bonded together with adhesive.

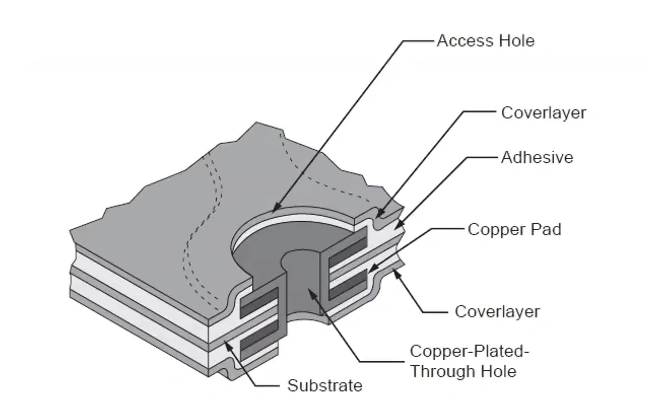

•Double-Layer FPC Structure

There is a copper foil layer on each side of the substrate. These copper foil layers are fixed to the substrate with adhesive or through lamination without adhesive. The outer layers are then covered with an additional adhesive and cover layer, creating the final double-layer FPC structure.

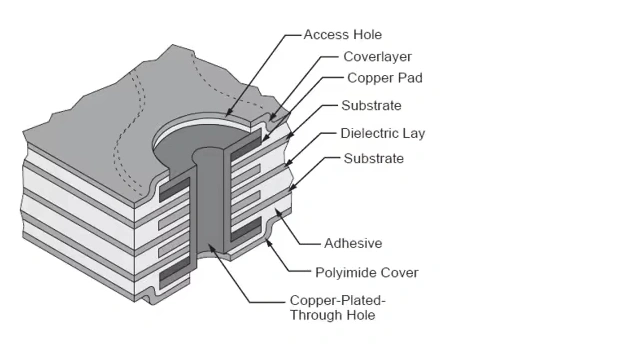

•Multi-Layer FPC Structure

A multi-layer FPC is composed of multiple single-layer or double-layer FPC stacked together.

In FPC stacking, the thickness of adhesive-free layers is thinner, making them more flexible in practice. The design of FPC stacking should include not only the stacking sequence but also the thickness and material information of each layer.

About Application Fields

Thanks to their unique characteristics like flexibility, thinness, and high - density circuit integration, FPC have found their way into a wide array of industries.

•Commercial electronic products

Such as: video recorders, video cameras, CD players, cameras, programmable telephones, personal computers, photocopiers, automobiles, electronic rangefinders and so on.

•Communication, military, aerospace field

Such as: aircraft black box, aircraft fuel controllers, accelerometers, missiles, infrared equipment, radar altimeter, artificial satellites, torpedoes and so on.

•Medical equipment field

Such as: blood analyser, hearing aid, drug transplant pump, bone age sensor, nerve stimulator, MRI, pacemaker, shielding, ultrasound detector and so on.

Or call +86 755 2794 4155

Inquiry Now