+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-11-20

2024-11-20

684

684

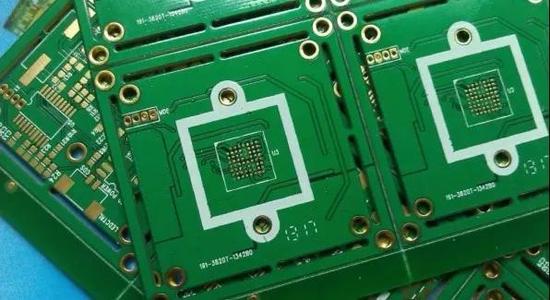

Ultra thin PCBs have unique specifications that make them highly suitable for specific applications where space and flexibility are of utmost importance.

The thickness of an ultra thin PCB is one of its most defining characteristics. Typically, these PCBs can have a thickness ranging from as little as 0.1mm to a few tenths of a millimeter. This extremely thin profile allows them to be used in applications where space is severely limited. For example, in modern smartphones and tablets, ultra thin PCBs enable the device manufacturers to make the products thinner and more compact. They can be easily integrated into the slim body of the device without adding significant bulk.

The materials used in ultra thin PCBs are carefully selected. Special substrate materials are often employed that have both good electrical properties and the required mechanical strength at such thin dimensions. For instance, flexible materials like polyimide are commonly used. Polyimide based substrates offer excellent flexibility, which is beneficial in applications where the PCB may need to be bent or conformed to a specific shape. This is crucial in wearable electronics, such as smart clothing or fitness trackers, where the PCB needs to be able to withstand the movements and bending of the human body without breaking.

In terms of the copper layer thickness, ultra thin PCBs also have specific requirements. The copper traces need to be thin enough to maintain the overall thinness of the board while still providing sufficient electrical conductivity. The copper thickness is usually carefully controlled to balance the electrical performance and the mechanical flexibility of the PCB. Additionally, the via (a connection between different layers of the PCB) design in ultra thin PCBs is different from that of traditional PCBs. The vias need to be small and have minimal impact on the overall thickness of the board. Special via filling techniques may be used to ensure reliable connections between the layers without adding excessive thickness.

The manufacturing process of ultra thin PCBs is highly precise. Advanced manufacturing techniques are required to ensure the uniformity of the substrate thickness, the quality of the copper deposition, and the integrity of the vias. Any small defect in the manufacturing process can have a significant impact on the performance of the ultra thin PCB.

Or call +86 755 2794 4155

Inquiry Now