+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2025-03-08

2025-03-08

804

804

Structure

Single layer board: A single layer PCB consists of only one layer of conductive material, usually copper, on one side of the insulating substrate. The other side is typically left uncoated or has only a solder mask or silk screen for markings. All the circuit traces, components, and connections are placed on this single conductive layer. It's like a one lane road where all the electrical signals have to travel in a single plane.

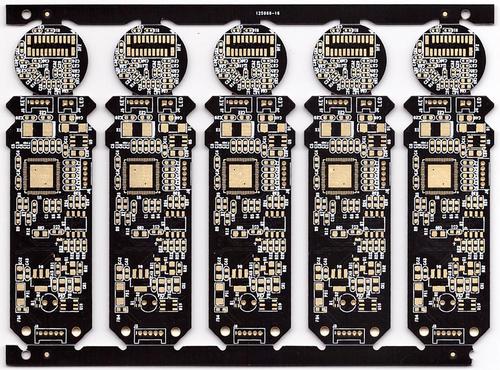

Multilayer board: Multilayer PCBs, on the other hand, are composed of multiple layers of conductive material separated by insulating layers. These layers can include signal layers, power planes, and ground planes. For example, a 4 layer board might have two signal layers sandwiching a power plane and a ground plane. This structure is similar to a multi lane highway with different lanes dedicated to different types of traffic (electrical signals).

Complexity of Circuit Design

Single layer board: Due to the limited space and the need to route all signals on a single layer, the circuit design for single layer boards is relatively simple. They are suitable for basic electronic circuits with a small number of components and connections. Designers have to be very careful to avoid signal crossovers and ensure that all the traces fit within the available space.

Multilayer board: Multilayer boards offer much more flexibility in circuit design. With multiple layers at their disposal, designers can route signals more efficiently, separate different types of signals (such as high speed and low speed signals) to different layers to reduce interference, and integrate a large number of components and complex circuitry. This makes them ideal for advanced electronic systems like smartphones, computers, and high end audio equipment.

Performance

Single layer board: Signal integrity can be a challenge on single layer boards, especially in high frequency applications. The lack of dedicated ground and power planes and the limited routing options can lead to signal distortion, crosstalk, and electromagnetic interference. However, for low frequency and simple circuits, they can provide satisfactory performance.

Multilayer board: The presence of dedicated power and ground planes in multilayer boards helps to improve signal integrity and reduce electromagnetic interference. The ability to control the impedance of different signal paths and the better separation of signals contribute to better overall performance, especially in high speed and high frequency applications.

Manufacturing Process

Single layer board: The manufacturing process for single layer boards is relatively straightforward and less costly. It involves fewer steps such as etching the single copper layer, drilling holes for components, and applying solder masks and silk screens.

Multilayer board: Manufacturing multilayer boards is more complex and time consuming. It requires precise alignment of multiple layers during lamination, careful etching of each layer to form the desired circuit patterns, and more extensive quality control to ensure the integrity of the internal layers and connections.

Cost

Single layer board: Generally, single layer boards are less expensive to produce. The lower manufacturing complexity, fewer materials, and simpler design requirements contribute to their lower cost, making them a cost effective choice for simple and low volume applications.

Multilayer board: Multilayer boards are more expensive due to their complex manufacturing process, the need for high precision equipment, and the use of additional materials. However, for applications where performance and space savings are critical, the higher cost is often justified.

Or call +86 755 2794 4155

Inquiry Now