+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-10-26

2024-10-26

998

998

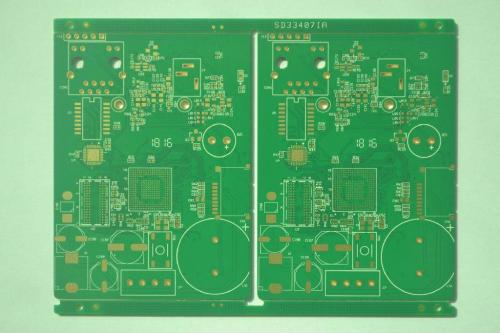

Printed Circuit Boards (PCBs) with standard specifications play a crucial role in various electronic applications. These PCBs are designed to meet common industry requirements and offer reliable performance.

The standard specification PCB typically consists of a rigid or flexible substrate material, such as FR-4 glass epoxy or polyimide. The substrate provides mechanical support and electrical insulation for the components and traces on the board.

The copper traces on a standard PCB are laid out according to the circuit design, connecting the various components such as resistors, capacitors, integrated circuits, and connectors. The trace width and spacing are usually determined based on the current-carrying capacity and signal integrity requirements.

Standard PCBs often have a defined number of layers, ranging from single-sided to multilayer configurations. Single-sided PCBs have components and traces on one side only, while double-sided PCBs have components and traces on both sides. Multilayer PCBs consist of multiple layers of copper traces and insulating layers, providing increased routing capacity and better electrical performance.

The standard specification PCB also includes features such as solder mask, silkscreen printing, and plated through-holes. The solder mask protects the copper traces from oxidation and provides insulation during soldering. Silkscreen printing is used to label components and provide identification marks on the board. Plated through-holes allow for electrical connections between different layers of the PCB.

standard specification PCBs are widely used in the electronics industry due to their reliable performance, cost-effectiveness, and ease of manufacturing. They provide a stable platform for electronic components and enable the efficient transfer of electrical signals.

Or call +86 755 2794 4155

Inquiry Now