+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2025-01-03

2025-01-03

694

694

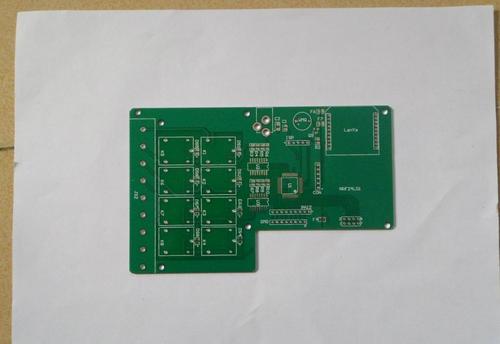

Small-size PCBs, also known as printed circuit boards, are widely used in various electronic devices where space is limited. These compact PCBs are designed to fit into small form-factor products such as wearable devices, miniature sensors, and some handheld electronics. The reduced size requires precise manufacturing techniques and careful component placement.

Manufacturers of small-size PCBs often use advanced technologies like high-density interconnect (HDI) to increase the number of connections and components that can be integrated within a limited area. This allows for the creation of more complex circuitry without sacrificing space. For example, in a smartwatch PCB, components like the microprocessor, memory chips, and sensors need to be arranged in a highly efficient manner to fit within the tiny enclosure.

The materials used for small-size PCBs also play a crucial role. They need to be lightweight and have good electrical properties. Flame-retardant materials are often preferred to ensure safety in case of overheating or short circuits. Additionally, the traces and vias on these PCBs are designed to be as thin and closely spaced as possible while maintaining proper conductivity.

Despite their small size, small-size PCBs must still meet strict performance requirements. They need to provide reliable power distribution, signal integrity, and thermal management. Designers use simulation tools to optimize the layout and predict potential issues such as crosstalk or impedance mismatches. small-size PCBs are essential for enabling the miniaturization trend in modern electronics, providing the necessary functionality in a compact and efficient package.

Or call +86 755 2794 4155

Inquiry Now