+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-09-26

2024-09-26

837

837

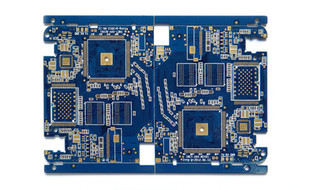

Single panel PCB (Printed Circuit Board) is a common electronic component carrier that plays an important role in electronic device manufacturing.

A single panel PCB typically consists of a layer of insulating substrate and a layer of conductive copper foil. The insulating substrate can be made of materials such as phenolic resin, glass fiber reinforced epoxy resin, etc., which have good insulation properties and mechanical strength. Conductive copper foil is formed into circuit patterns through etching and other processes, connecting various electronic components.

In terms of design, single panel PCBs are relatively simple. Due to the presence of conductive lines on only one side, the layout is more intuitive and easy to design and manufacture. For some simple electronic circuits, such as control circuits for small electronic products, simple sensor circuits, etc., single panel PCB is an economical choice.

In terms of production technology, the production process of single panel PCB is relatively simple. Firstly, the designed circuit pattern is transferred onto copper foil through photolithography and other techniques, and then etched to remove unwanted copper foil parts, leaving behind the desired circuit lines. Next, drilling, plug-in installation, welding and other processes are carried out to complete the production of the circuit board.

The advantages of single panel PCB mainly include the following: first, low cost. Due to its simple structure and relatively easy manufacturing process, single panel PCBs have a relatively low price and are suitable for large-scale production and low-cost electronic product applications. The second is high reliability. The circuit structure of a single panel PCB is simple, reducing potential failure points and improving product reliability. Thirdly, it is easy to maintain. If a malfunction occurs, maintenance personnel can easily locate the problem on the single panel and carry out repairs.

However, single panel PCBs also have some limitations. Due to the presence of conductive lines on only one side, the circuit layout is subject to certain limitations and may not meet the design requirements of complex circuits. In addition, the signal transmission performance of single panel PCB is relatively weak, which may be affected by interference and affect the performance of the circuit.

In short, single panel PCBs have a wide market in the application of simple electronic circuits due to their advantages of low cost, high reliability, and easy maintenance. But with the continuous development of electronic technology, double-sided and multi-layer PCB have gradually become mainstream for more complex circuit designs.

Or call +86 755 2794 4155

Inquiry Now