+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-08-15

2024-08-15

842

842

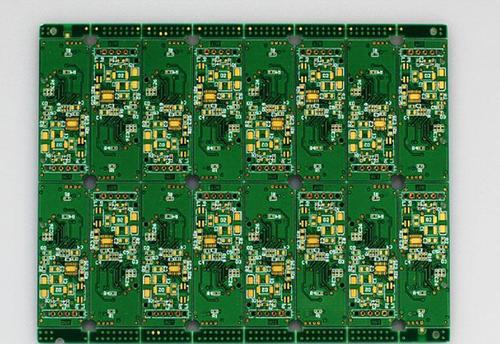

Printed Circuit Board Assembly (PCBA) refers to a printed circuit board that has been assembled and soldered, containing various electronic components. It is the process of making a PCB board from a designed circuit diagram through plate making, etching, drilling, and other processes, and then soldering various electronic components (such as resistors, capacitors, transistors, integrated circuits, etc.) onto the PCB board according to the requirements of the circuit design, forming electronic modules or systems with specific functions.

PCBA is the core part of modern electronic product manufacturing, widely used in various fields such as consumer electronics, communication equipment, industrial control, medical instruments, automotive electronics, etc. It not only achieves the integration and miniaturization of electronic components, but also improves the stability and reliability of circuits, simplifying the assembly and maintenance process of electronic products.

In the production process of PCBA, manufacturers typically use advanced production equipment and technologies such as surface mount technology (SMT), automatic optical inspection (AOI), X-ray inspection (AXI), etc. to ensure product quality and performance. In addition, in order to meet the needs of different customers, manufacturers also need to have flexible production scheduling capabilities and strong supply chain management capabilities, providing one-stop services from component procurement, assembly, testing to packaging, logistics, etc.

Or call +86 755 2794 4155

Inquiry Now