+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-12-19

2024-12-19

130

130

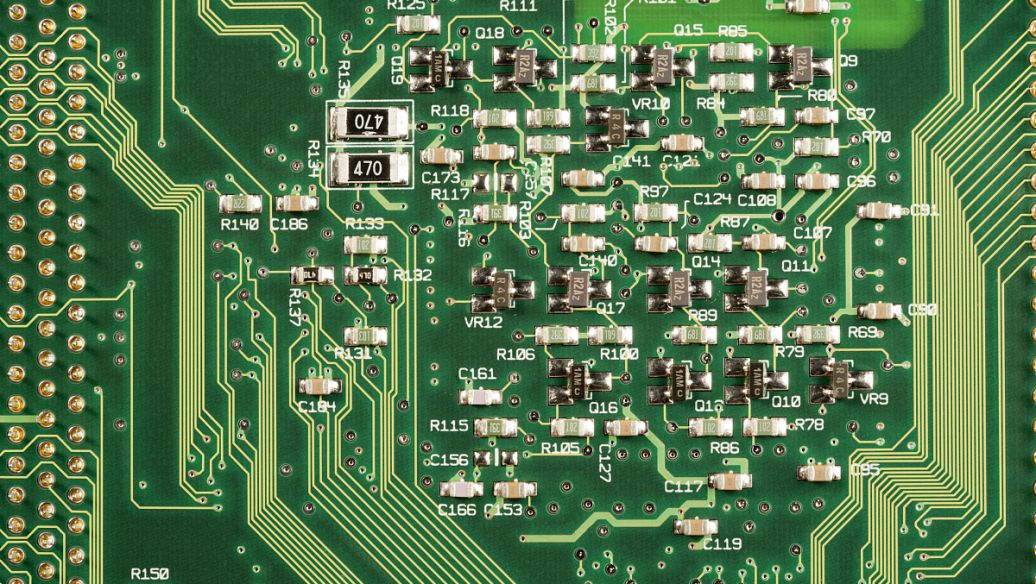

Printed Circuit Board (PCB) mass production is a complex and highly specialized process that requires precision, efficiency, and quality control. The goal of PCB mass production is to produce large quantities of PCBs in a cost-effective and timely manner while maintaining high quality standards.

The first step in PCB mass production is the design and layout of the circuit board. This involves creating a detailed schematic diagram and then converting it into a physical layout using specialized software. The layout must take into account factors such as component placement, signal routing, and power distribution to ensure optimal performance and reliability.

Once the design is complete, the next step is to manufacture the PCBs. This typically involves a series of processes such as etching, drilling, plating, and printing. Etching is used to remove unwanted copper from the board, while drilling creates holes for components and vias. Plating is then used to add conductive layers to the board, and printing is used to add labels and markings.

During mass production, quality control is essential to ensure that each PCB meets the required specifications. This involves a series of inspections and tests at various stages of the production process. For example, visual inspections are performed to check for defects such as scratches, blemishes, and missing components. Electrical tests are also conducted to ensure that the board functions properly and meets the required electrical specifications.

In addition to quality control, efficiency is also a key consideration in PCB mass production. This involves optimizing the production process to minimize waste, reduce production time, and increase throughput. This can be achieved through techniques such as automated manufacturing, lean production principles, and continuous improvement.

PCB mass production is a complex and challenging process that requires a combination of technical expertise, quality control, and efficiency. By following best practices and using advanced manufacturing techniques, it is possible to produce high-quality PCBs in large quantities while meeting tight deadlines and cost constraints.

Or call +86 755 2794 4155

Inquiry Now