+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-10-23

2024-10-23

831

831

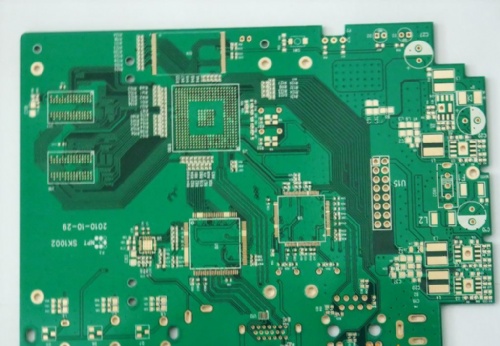

PCB electroplating gold is a process that deposits a layer of gold onto the surface of a printed circuit board (PCB) through an electrochemical reaction. This process is commonly used to improve the electrical conductivity, solderability, and corrosion resistance of PCBs.

The electroplating gold process typically involves several steps. First, the PCB is cleaned and prepared to ensure a clean and smooth surface for the gold plating. Then, a thin layer of a conductive material, such as copper or nickel, is applied to the PCB to provide a base for the gold plating. Next, the PCB is immersed in an electroplating bath containing a gold salt solution and an electrical current is passed through the bath. The electrical current causes the gold ions in the solution to be reduced and deposited onto the surface of the PCB, forming a layer of gold.

One of the main advantages of electroplating gold is that it can provide a very thin and uniform layer of gold on the PCB surface. This can be beneficial for applications where space is limited or where a very thin layer of gold is required for electrical conductivity. Additionally, electroplating gold can provide excellent corrosion resistance and solderability, making it ideal for use in harsh environments or for high-reliability applications.

However, electroplating gold also has some limitations. It can be a relatively expensive process compared to other surface finishing methods, and it may require specialized equipment and expertise. Additionally, the gold layer may be prone to wear and tear over time, especially if the PCB is subjected to mechanical stress or abrasion.

PCB electroplating gold is a useful process for improving the performance and reliability of printed circuit boards. However, it should be carefully considered in terms of cost, durability, and application requirements before being selected as a surface finishing method.

Or call +86 755 2794 4155

Inquiry Now