+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-12-25

2024-12-25

432

432

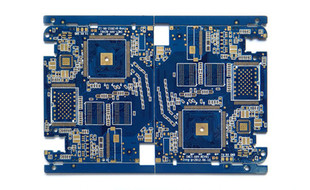

Military printed circuit boards (PCBs) play a vital and unique role in defense applications. These PCBs are designed to meet extremely high standards due to the critical nature of military equipment and operations.

Firstly, in terms of reliability, military PCBs must be able to function flawlessly under harsh and diverse conditions. They may be exposed to extreme temperatures, ranging from the intense heat of deserts to the freezing cold of high-altitude or polar regions. They also need to withstand significant mechanical vibrations and shocks that occur during transportation, deployment, or in combat scenarios. For example, in military vehicles, aircraft, or naval vessels, the PCBs installed in communication systems, navigation devices, and weapon control systems must remain operational without any failures.

The materials used for military PCBs are carefully selected for their durability and performance. High-quality substrates with excellent thermal management properties are employed to ensure that the heat generated by the electronic components on the PCB can be dissipated effectively. Moreover, the copper traces on the PCB are designed with precise widths and thicknesses to handle high currents and maintain signal integrity.

Security is another crucial aspect. Military PCBs often incorporate encryption and anti-tampering features. This is to prevent unauthorized access to the electronic systems they are part of and safeguard sensitive military information. In addition, strict manufacturing and testing processes are followed. Each PCB undergoes multiple rounds of rigorous inspections and tests, including electrical performance tests, environmental endurance tests, and reliability assessments to guarantee that it meets the exacting requirements of military applications. military PCBs are at the heart of the advanced and reliable electronic systems that support military operations.

Or call +86 755 2794 4155

Inquiry Now