+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-12-18

2024-12-18

611

611

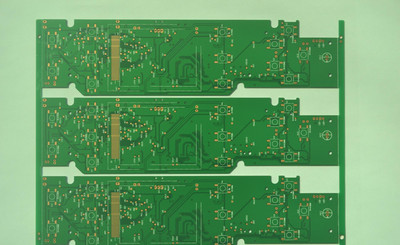

Low-cost PCB materials are of great interest in the electronics industry, especially for mass-produced consumer electronics and applications where cost is a major constraint. One of the commonly used low-cost PCB materials is phenolic paper laminate. It is made from paper impregnated with phenolic resin. This material has relatively low manufacturing costs due to the inexpensive raw materials and simple manufacturing process. It is suitable for applications where the electrical and mechanical requirements are not extremely high, such as simple electronic toys, basic consumer electronics with low power consumption, and some educational electronics kits.

Another low-cost option is FR-4, which is a fiberglass-reinforced epoxy laminate. It has been widely used in the electronics industry for decades. FR-4 offers a good balance between cost and performance. It has acceptable electrical and mechanical properties for many mid-range applications. It can be used for circuit boards in computers, printers, and other office equipment. The availability and large-scale production of FR-4 also contribute to its low cost.

However, it's important to note that while low-cost PCB materials can save on production expenses, they may have limitations in terms of performance. For example, their thermal conductivity may not be as high as that of high-performance materials, which could limit their use in high-power applications. Their dielectric properties may also not be suitable for very high-frequency circuits. But for applications where cost-effectiveness is the top priority and the performance requirements can be met, low-cost PCB materials provide an economical solution. They allow manufacturers to produce electronic products at a lower cost and make them more accessible to a wider range of consumers.

Or call +86 755 2794 4155

Inquiry Now