+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-10-11

2024-10-11

370

370

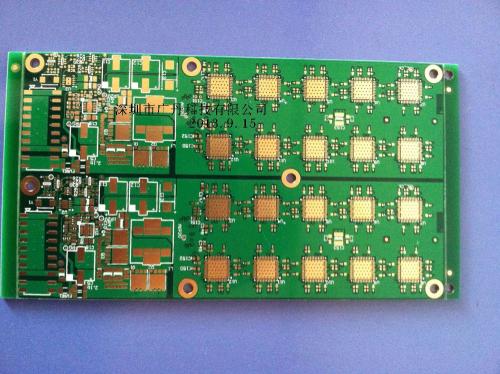

LED lighting Printed Circuit Boards (PCBs) play a crucial role in the efficient functioning of modern lighting systems. These PCBs are specifically designed to meet the unique requirements of LED lights, providing a stable and reliable platform for the LEDs to operate.

The design of an LED lighting PCB is a complex process that takes into account various factors such as the number and type of LEDs to be used, the power requirements, heat dissipation, and electrical isolation. The PCB must be able to handle the high currents and voltages associated with LED lighting while also providing a path for heat to escape to prevent damage to the LEDs.

One of the key features of an LED lighting PCB is its ability to distribute power evenly to each LED. This is achieved through the use of specialized circuitry and components that ensure a consistent voltage and current supply. The PCB may also include features such as dimming controls, color temperature adjustment, and fault detection to enhance the functionality and usability of the lighting system.

In addition to electrical performance, the physical design of the PCB is also important. The PCB must be able to fit within the housing of the lighting fixture and be compatible with the manufacturing process. This may involve considerations such as board thickness, component placement, and solderability.

Furthermore, LED lighting PCBs are often designed to be environmentally friendly. They may use lead-free solder and materials that are recyclable or biodegradable. This helps to reduce the environmental impact of the lighting system and meet the growing demand for sustainable products.

Or call +86 755 2794 4155

Inquiry Now