+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-11-26

2024-11-26

323

323

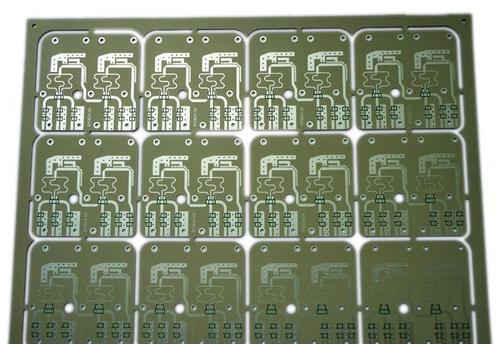

Quality control is essential for ensuring the reliability and performance of printed circuit boards (PCBs). Here are some key points to consider for PCB quality control:

1. Design Review: Conduct a thorough design review before manufacturing the PCB. Check for design errors, compatibility issues, and potential manufacturing problems. Ensure that the design meets the required specifications and standards.

2. Material Inspection: Inspect the materials used for PCB manufacturing, such as copper foil, laminate, and components. Ensure that the materials are of high quality and meet the required specifications. Check for any defects or contaminants that could affect the quality of the PCB.

3. Manufacturing Process Control: Monitor and control the manufacturing process to ensure consistent quality. This includes processes such as etching, plating, drilling, and soldering. Use quality control tools and techniques such as statistical process control (SPC) to detect and correct any process variations.

4. Electrical Testing: Perform electrical testing on the PCB to ensure that it functions properly. This includes tests such as continuity testing, insulation resistance testing, and functional testing. Use automated testing equipment to improve testing efficiency and accuracy.

5. Visual Inspection: Conduct a visual inspection of the PCB to check for any physical defects such as scratches, cracks, or missing components. Use magnifying glasses and inspection tools to ensure that the PCB meets the required quality standards.

6. Environmental Testing: Subject the PCB to environmental testing to ensure that it can withstand the intended operating conditions. This includes tests such as temperature cycling, humidity testing, and vibration testing.

7. Documentation and Traceability: Maintain proper documentation and traceability for the PCB manufacturing process. This includes records of materials used, manufacturing processes, testing results, and any corrective actions taken. This helps to ensure accountability and quality control.

8. Supplier Quality Management: Manage the quality of your PCB suppliers to ensure that they provide high-quality materials and services. Establish quality agreements with suppliers and conduct regular audits to ensure compliance.

By following these key points of PCB quality control, you can ensure that your PCBs are of high quality and reliable performance. This can help reduce the risk of failures and improve the overall quality of your products.

Or call +86 755 2794 4155

Inquiry Now