+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-11-12

2024-11-12

651

651

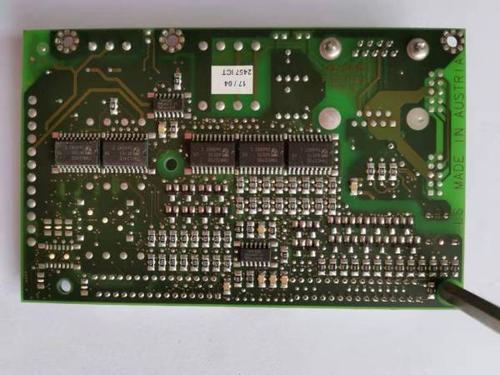

High - thermal - conductivity printed circuit boards (PCBs) play a crucial role in electronic devices where efficient heat dissipation is essential. These PCBs are designed to manage heat effectively, thereby improving the reliability and performance of the overall system.

The materials used in high - thermal - conductivity PCBs are the key to their heat - dissipating capabilities. One common approach is to use metal - based substrates. For example, aluminum - based PCBs are widely used. The aluminum core provides an excellent heat - conducting path. The copper layers on the PCB are laminated onto the aluminum substrate, allowing heat generated by the components to be quickly transferred to the aluminum and then dissipated into the surrounding environment. Another option is to use ceramic - based materials. Ceramic substrates have high thermal conductivity and can withstand high temperatures. They are often used in high - power applications such as power amplifiers and LED lighting systems.

In addition to the substrate material, the design of the PCB layout also affects heat dissipation. The placement of components is carefully considered. High - power components, such as power transistors or integrated circuits that generate significant amounts of heat, are usually distributed evenly across the PCB to avoid hot spots. The copper traces are designed not only for electrical connectivity but also to act as heat - spreading paths. Wider copper traces can be used in areas near heat - generating components to increase the heat - conducting area. Thermal vias are also an important design element. These vias are filled with a thermally conductive material and connect the different layers of the PCB, allowing heat to be transferred more effectively between the layers.

The manufacturing process of high - thermal - conductivity PCBs requires special attention. When laminating the copper layers onto the substrate, the bonding process must ensure good thermal contact. For metal - based substrates, techniques such as pressure - bonding are used to minimize any air gaps between the layers, as air is a poor conductor of heat. In ceramic - based PCBs, the firing process needs to be carefully controlled to achieve the desired density and thermal properties of the ceramic material.

Moreover, the surface treatment of high - thermal - conductivity PCBs can also impact heat transfer. A smooth and clean surface can enhance the contact with heat sinks or other cooling devices. Coatings or finishes that do not impede heat flow are preferred. high - thermal - conductivity PCBs are essential for applications where heat management is critical to ensure the proper functioning and longevity of electronic components.

Or call +86 755 2794 4155

Inquiry Now