+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-11-25

2024-11-25

840

840

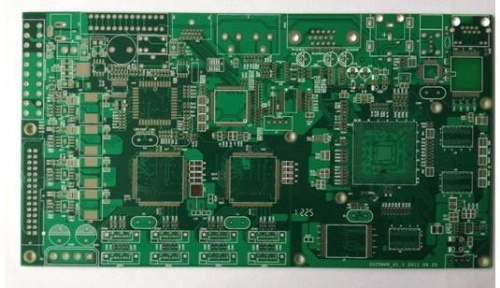

In today's complex electronic systems, high reliability printed circuit boards (PCBs) are essential. A high reliability PCB is designed and manufactured to ensure consistent performance and durability even in demanding environments.

One of the key factors in achieving high reliability is the selection of quality materials. Premium-grade substrates, copper foils, and soldermasks are used to ensure excellent electrical insulation, thermal conductivity, and mechanical strength. These materials are carefully chosen to withstand temperature variations, humidity, and mechanical stress.

The design process also plays a crucial role. Engineers use advanced design software and follow strict design guidelines to optimize the layout for signal integrity, power distribution, and thermal management. This includes minimizing signal interference, providing proper grounding, and ensuring efficient heat dissipation.

Manufacturing processes are equally important. High reliability PCBs are typically produced using state-of-the-art manufacturing techniques such as automated optical inspection (AOI), automated X-ray inspection (AXI), and in-circuit testing (ICT). These processes help detect and correct any defects early in the production cycle, ensuring a high-quality final product.

Furthermore, quality control measures are implemented at every stage of production. Rigorous testing is conducted to ensure that the PCBs meet or exceed industry standards for electrical performance, reliability, and durability. This may include environmental testing, such as temperature cycling and humidity testing, to simulate real-world conditions.

In applications where failure is not an option, such as in aerospace, medical devices, and military systems, high reliability PCBs are a must. These PCBs provide the confidence that the electronic system will operate reliably over a long period, reducing the risk of downtime and costly repairs.

high reliability PCBs are the result of careful material selection, advanced design, precise manufacturing, and strict quality control. They are essential for ensuring the performance and longevity of critical electronic systems.

Or call +86 755 2794 4155

Inquiry Now