+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-10-29

2024-10-29

642

642

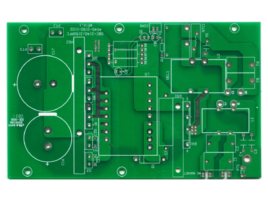

High-precision printed circuit boards (PCBs) are essential for applications that demand exceptional electrical performance and reliability. These PCBs require strict specification requirements to ensure accurate and consistent functionality.

One of the key requirements for high-precision PCBs is tight dimensional tolerance. The board dimensions, hole locations, and trace widths and spacings must be controlled within very narrow limits to ensure proper component placement and signal integrity. This often requires advanced manufacturing processes and precision machinery.

High-precision PCBs also require excellent surface finish. The copper surfaces must be smooth and free from defects to ensure good solderability and electrical conductivity. Common surface finishes for high-precision PCBs include immersion gold, electroless nickel/immersion gold (ENIG), and organic solderability preservative (OSP).

Signal integrity is another critical aspect of high-precision PCBs. The traces must be designed to minimize signal loss, crosstalk, and electromagnetic interference. This may involve using controlled impedance traces, proper grounding techniques, and shielding.

For applications that require high-frequency operation, high-precision PCBs need to have low dielectric loss and controlled dielectric constant. This ensures that the signals propagate with minimal distortion and attenuation.

In addition to electrical performance, high-precision PCBs may also have specific mechanical requirements. For example, they may need to be able to withstand high temperatures, vibrations, and mechanical stress.

high-precision PCBs have stringent specification requirements to meet the demands of advanced electronic applications. These requirements include tight dimensional tolerance, excellent surface finish, signal integrity, low dielectric loss, and specific mechanical properties. By meeting these requirements, high-precision PCBs can provide reliable and accurate performance in critical applications.

Or call +86 755 2794 4155

Inquiry Now