+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2025-04-10

2025-04-10

988

988

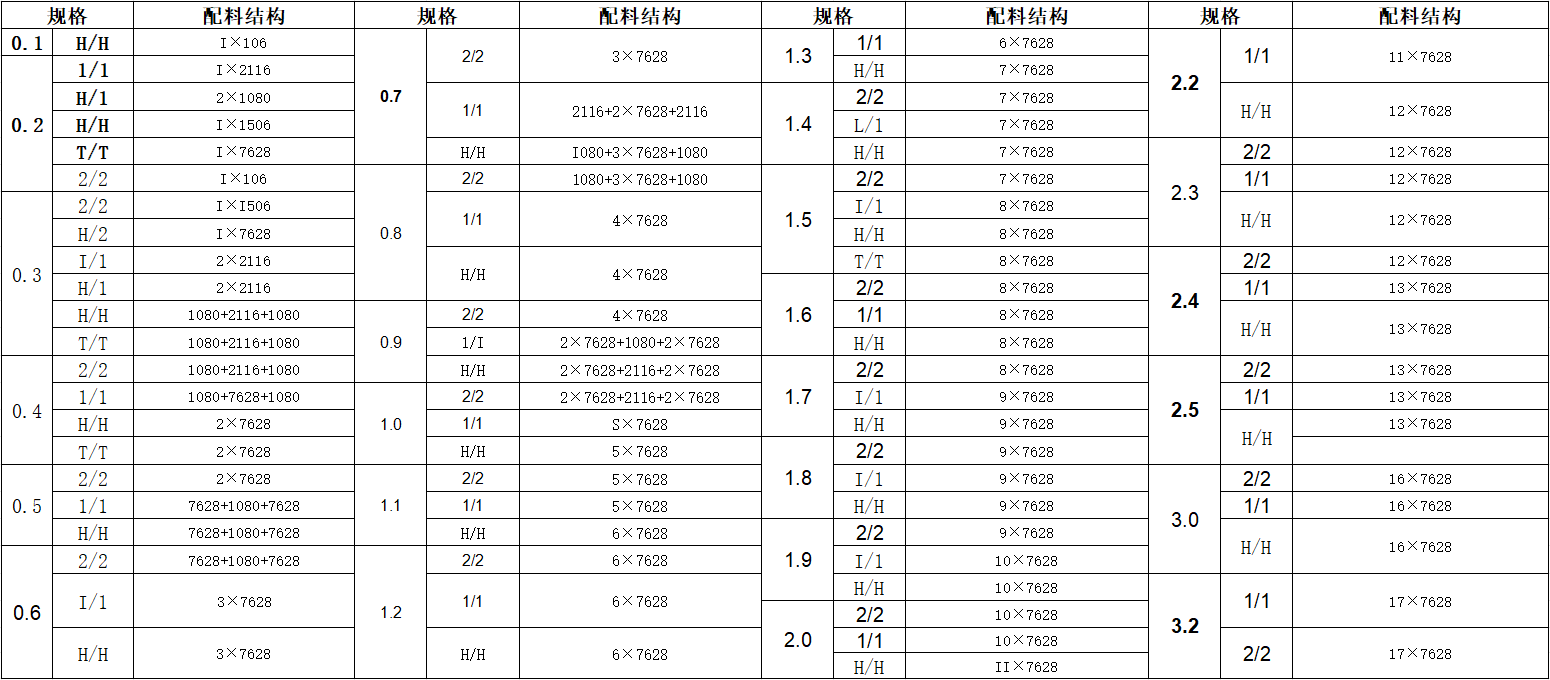

Material Costs

The choice of substrate material (e.g., FR-4, high-frequency materials) significantly impacts costs. Specialty materials typically come at a premium.

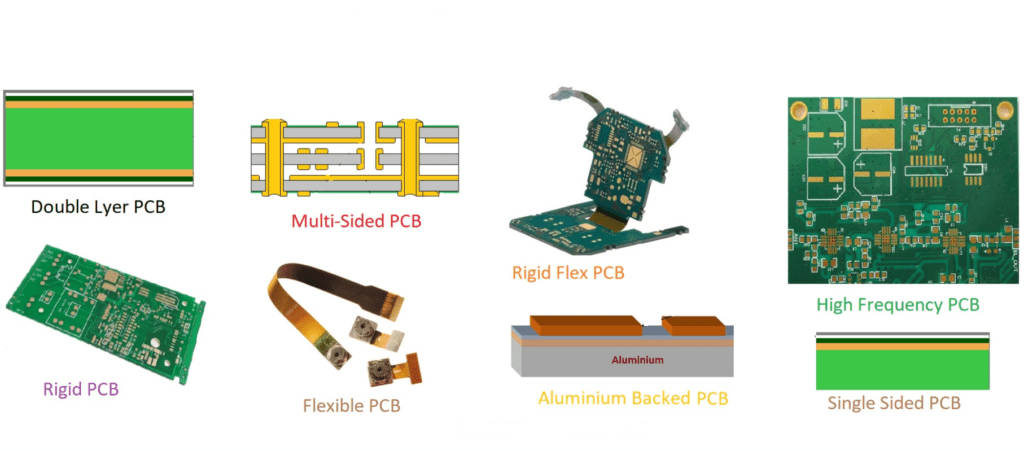

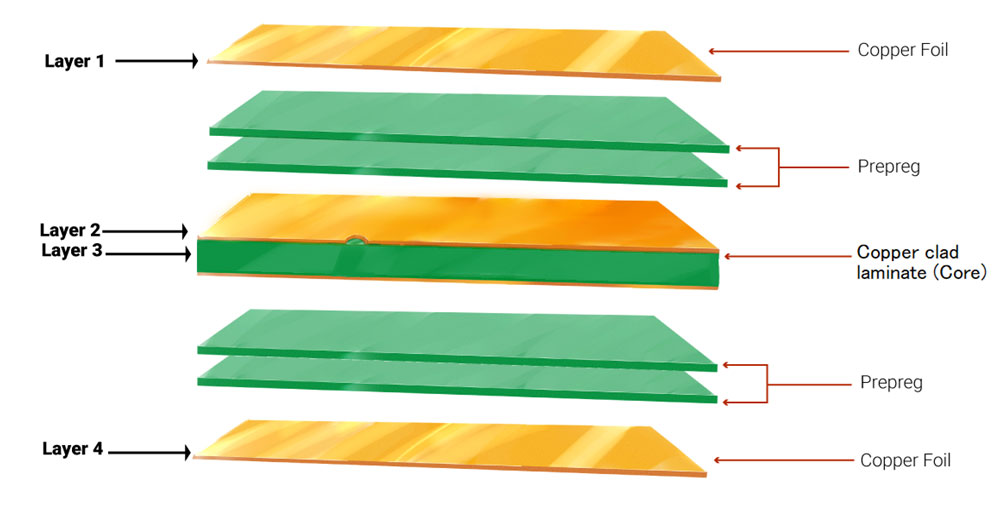

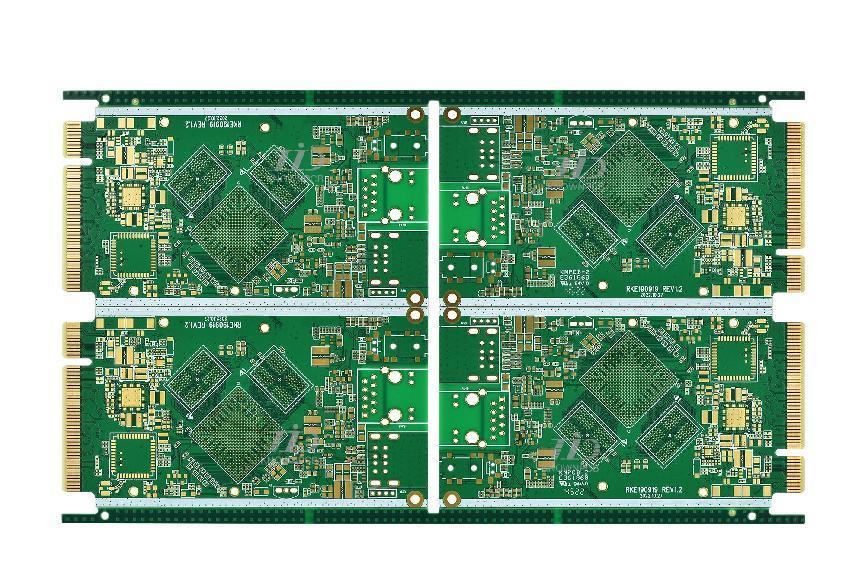

Layer Count

The number of layers in a PCB affects manufacturing complexity and cost. More layers generally lead to higher prices.

Board Size and Thickness

Larger and thicker boards require more material and may also need specialized handling, increasing costs.

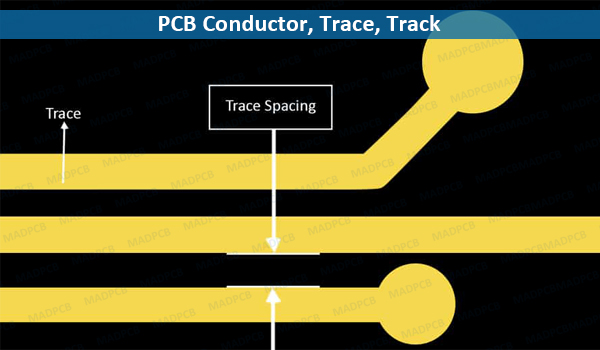

Trace Width and Spacing

Narrower traces and tighter spacing require more precise manufacturing processes, which can raise costs.

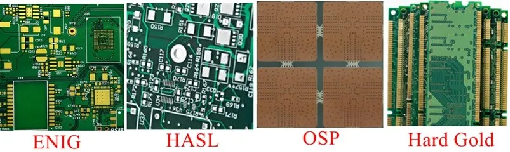

Surface Finish

Different surface finishes (e.g., HASL, ENIG) have varying costs associated with them. Some finishes are more expensive but provide better perfo.

Volume and Order Size

Larger prucodtion runs typically reduce the per-unit cost due to economies of scale, while small batches may be more expensive on a per-board basis.

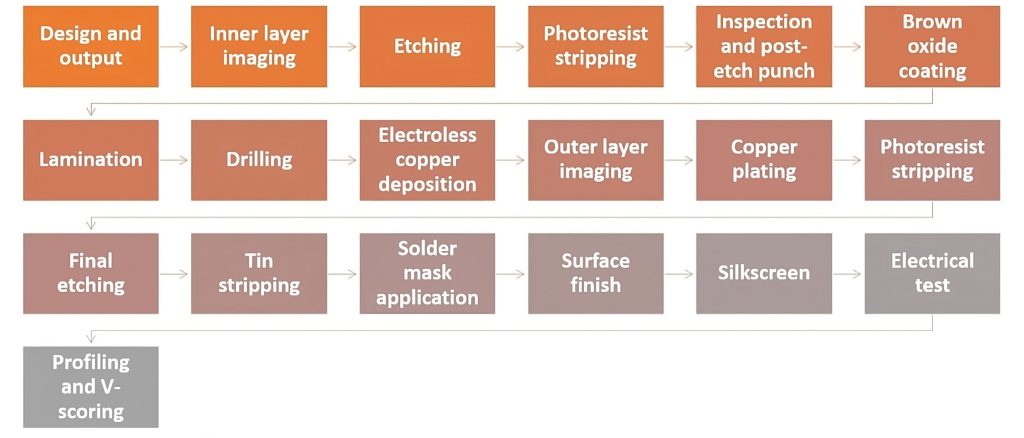

Manufacturing Process

The complexity of the manufacturing process (e.g., automated vs. manual assembly) can impact costs. Processes that require more labor or specialized equipment tend to be pricier.

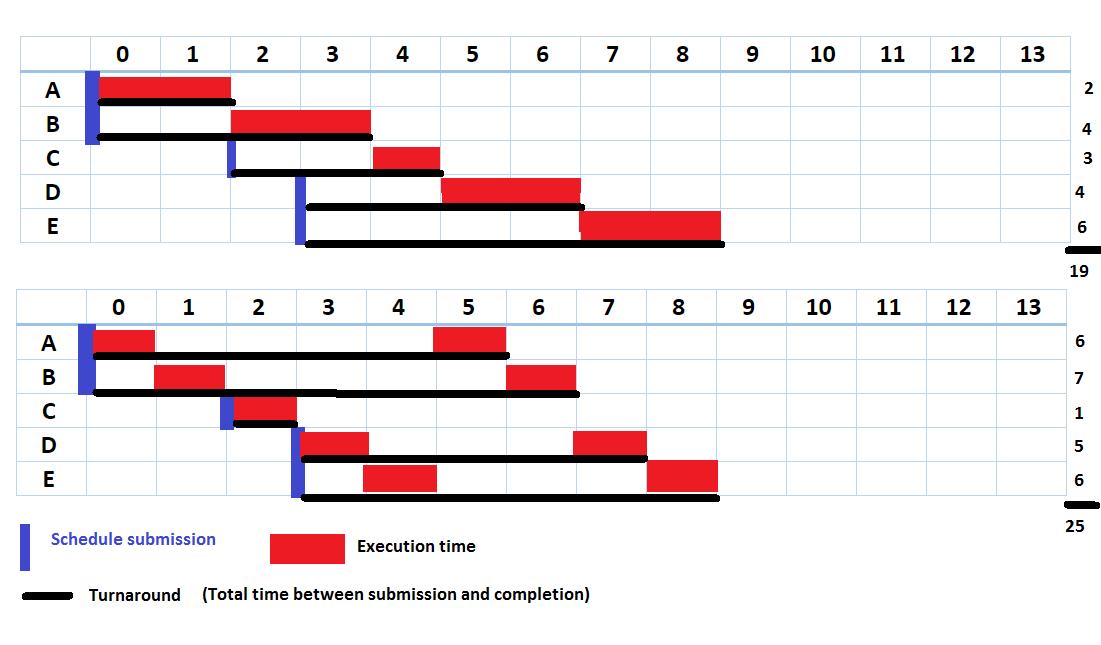

Turnaround Time

Expedited production services often come with a premium. Standard lead times are more cost-effective.

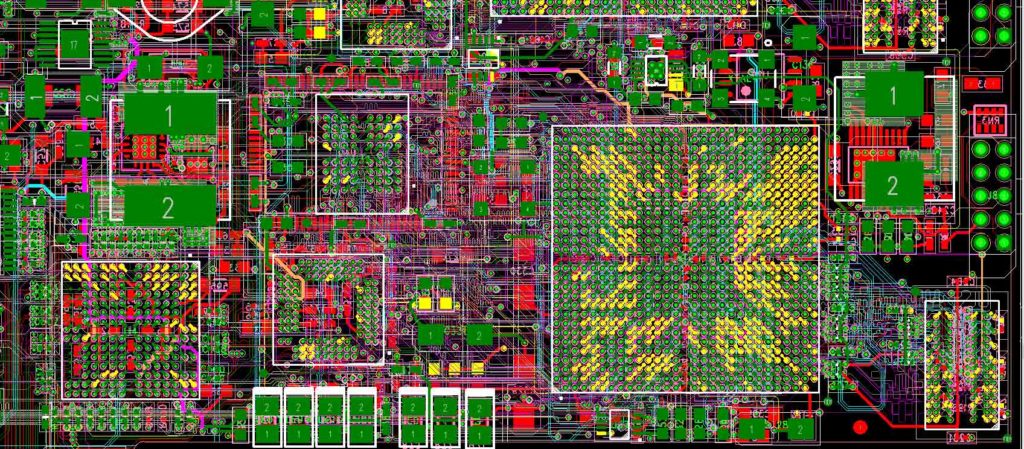

Design Complexity

Complex designs that require advanced manufacturing techniques (like blind/buried vias or high-density interconnections) can increase costs.

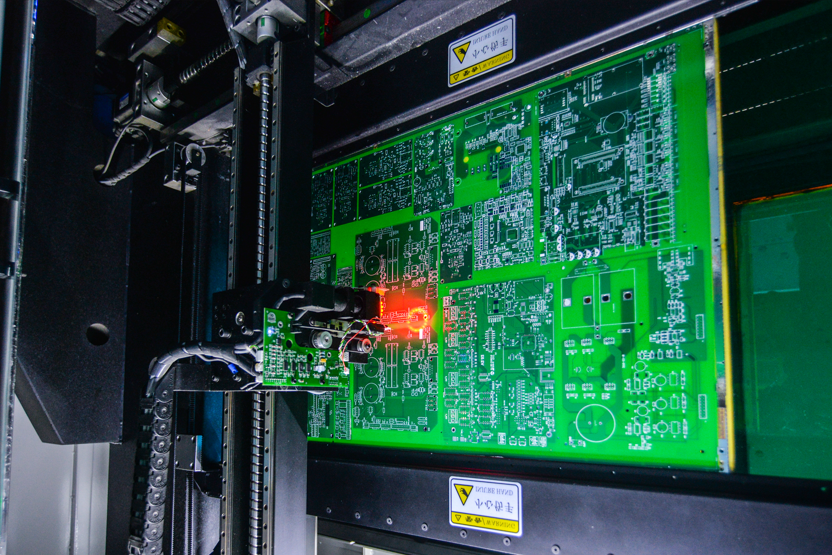

Testing and Inspection

Additional testing procedures (e.g., electrical testing, X-ray inspection) can add to the overall price of the PCB.

Shipping and Logistics

Costs associated with shipping, especially for international orders, can affect the overall price.

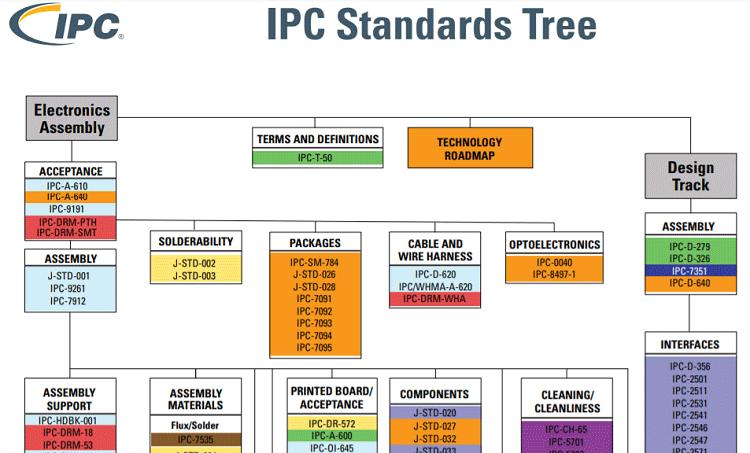

Regulatory Compliance

Compliance with industry standards (e.g., RoHS, IPC) may necessitate additional processes, influencing costs.

By understanding these factors, you can make more informed decisions when budgeting for PCB production.

Or call +86 755 2794 4155

Inquiry Now