+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2025-03-18

2025-03-18

293

293

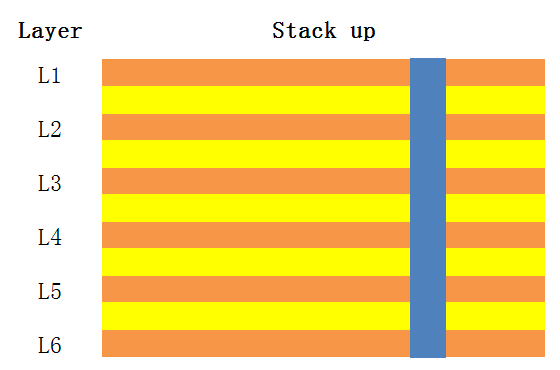

Via

A common type of hole is used for conducting or connecting copper foil lines between conductive patterns in different layers of a circuit board. But copper plated holes for component legs or other reinforcing materials cannot be inserted.

• Characteriscits

In order to meet customer needs, the conductive holes of the circuit board must be plugged. This way, in changing the traditional aluminum sheet plugging process, blank mesh is used to complete the solder mask and plug holes on the circuit board surface, making its production stable, quality reliable, and application more complete.

• Function

Connect and conduct circuits to each other.

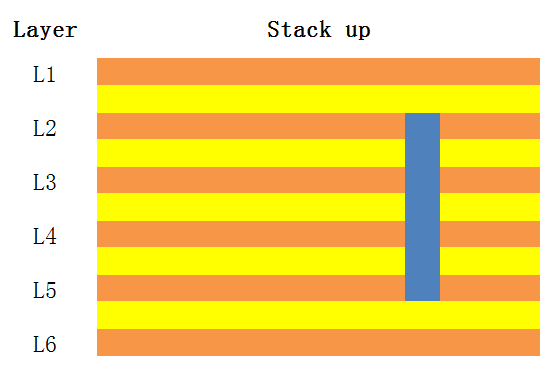

Buried Hole

The connection between any circuit layer inside the PCB, but not conducting to the outer layer, also refers to the through-hole that does not extend to the surface of the circuit board.

• Characteriscits

In this process, drilling after bonding cannot be achieved. Drilling must be performed on individual circuit layers, with partial bonding of the inner layer followed by electroplating treatment before fully bonding, which is more labor-intensive than the original through holes and blind holes, making it the most expensive.

• Function

Electrical connections, fixed components.

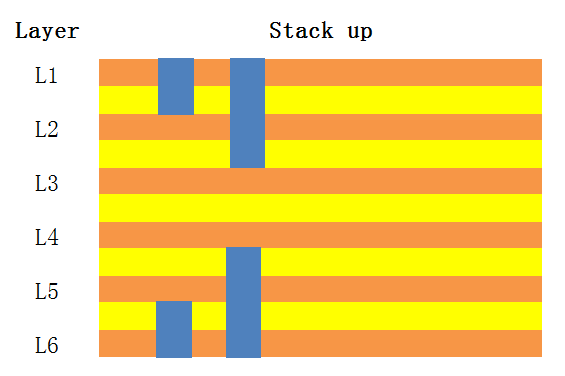

Blind Hole

Connecting the outermost circuit in the PCB with adjacent inner layers through plated holes is called blind pass because the opposite side cannot be seen. Blind holes are also conductive holes on one surface of the printed circuit board to increase the utilization of space between PCB circuit layers.

• Characteriscits

In this process, drilling after bonding cannot be achieved. Drilling must be performed on individual circuit layers, with partial bonding of the inner layer followed by electroplating treatment before fully bonding, which is more labor-intensive than the original through holes and blind holes, making it the most expensive.

• Particular Attention

If not careful, it can cause difficulties in electroplating inside the hole, and laser drilling is usually used for operation; There are also a few who use mechanical drilling methods(Drill holes in individual circuit layers that need to be connected in advance, and then bond them together, but it requires precise positioning and alignment devices to complete) for operations.

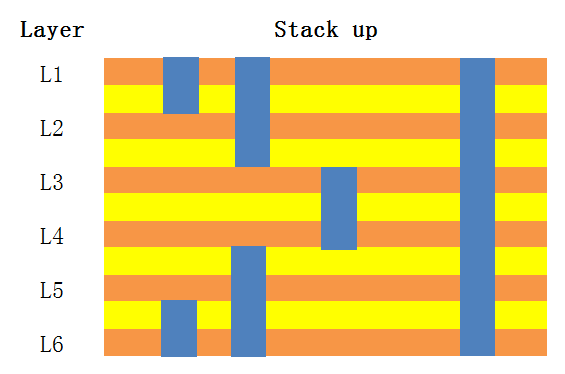

The above image is a common six layer HDI Stack up diagram

Or call +86 755 2794 4155

Inquiry Now