+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-09-03

2024-09-03

922

922

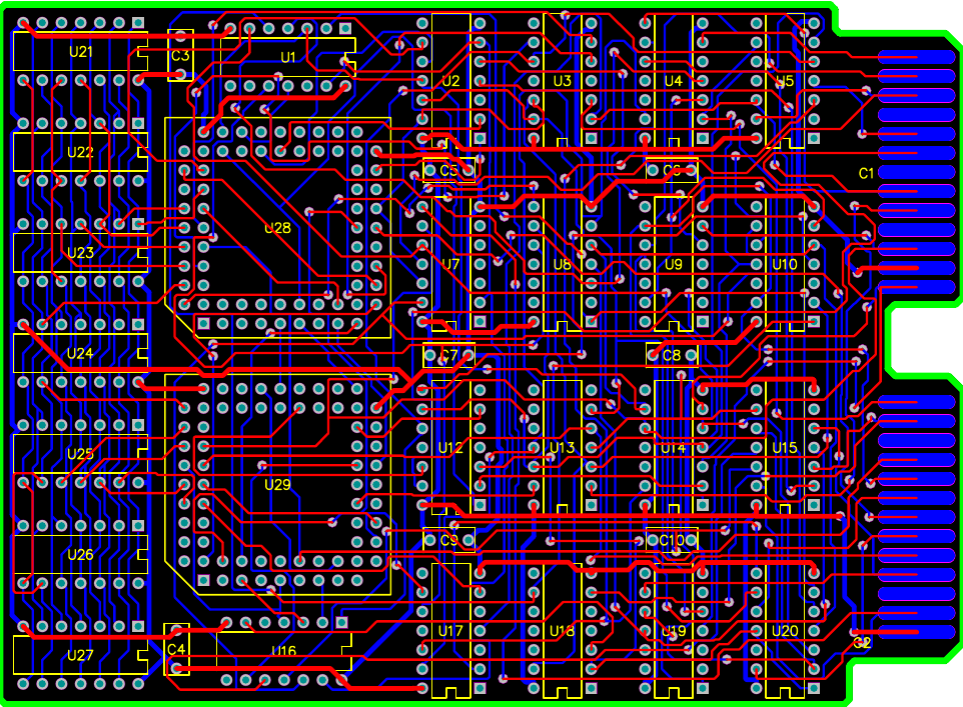

1. Layout according to circuit modules, and the relevant circuits that achieve the same function are called a module. The components in the circuit module should adopt the principle of proximity, and digital circuits and analog circuits should be separated;

2. No components or parts shall be mounted within 1.27mm around non installation holes such as positioning holes and standard holes. No components or parts shall be mounted within 3.5mm (for M2.5) or 4mm (for M3) around installation holes such as screws;

3. Avoid laying through holes underneath components such as resistors, inductors (plugs), electrolytic capacitors, etc. to prevent short circuits between the through holes and the component housing after wave soldering;

The distance between the outer side of the component and the edge of the board is 5mm;

5. The distance between the outer side of the component solder pad and the outer side of the adjacent plug-in component is greater than 2mm;

6. Metal shell components and metal parts (shielding boxes, etc.) should not collide with other components, and should not be tightly attached to printed lines or solder pads. The distance between them should be greater than 2mm. The distance between the outer side of positioning holes, fastener installation holes, elliptical holes, and other square holes in the plate and the edge of the plate is greater than 3mm;

7. Heating elements should not be placed in close proximity to wires and thermal sensitive elements; High temperature components should be evenly distributed;

8. Power sockets should be arranged around the printed circuit board as much as possible, and the power sockets and their connected bus terminals should be arranged on the same side. Special attention should be paid not to arrange power sockets and other welding connectors between the connectors, in order to facilitate the welding of these sockets and connectors, as well as the design and wiring of power cables. The spacing between power sockets and welding connectors should be considered to facilitate the insertion and removal of power plugs;

9. Layout of other components for PCB board sampling:

Or call +86 755 2794 4155

Inquiry Now