+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-07-19

2024-07-19

200

200

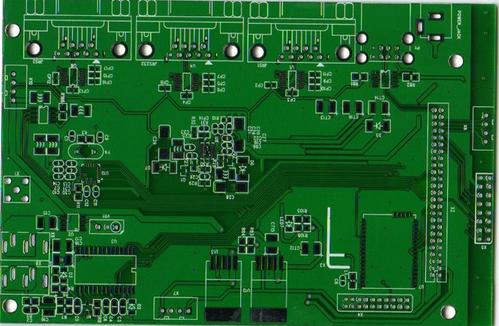

PCB (Printed Circuit Board) is the cornerstone of modern electronics industry. It not only carries various electronic components, but also is responsible for their electrical connections and signal transmission. The manufacturing process of PCB is very complex, including multiple steps such as circuit design, etching, drilling, plating, etc. Each link requires precise equipment and technology.

In the production process of PCB, it is necessary to first generate film according to the circuit design drawings, and then transfer the circuit patterns onto the substrate through processes such as exposure, development, and etching. Next, drilling and coating treatment will be carried out to ensure the conductivity and anti-interference of the circuit. Finally, only qualified PCB products can enter the market after strict quality inspection and packaging.

There are many types of PCBs, which can be divided into single-layer boards, double-layer boards, multi-layer boards, etc. according to the number of layers; According to the material, it can be divided into different types such as FR-4, CEM-3, Rogers, etc. Different application scenarios also have different requirements for PCBs. For example, high-frequency communication equipment requires the use of low loss, high dielectric constant materials, while consumer electronics products focus more on cost and reliability.

In short, as a key component of electronic devices, the quality and performance of PCB printed circuit boards directly affect the stability and service life of the entire system. Therefore, when selecting and using PCBs, various factors must be fully considered to ensure that they meet actual needs.

Or call +86 755 2794 4155

Inquiry Now