+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-09-20

2024-09-20

627

627

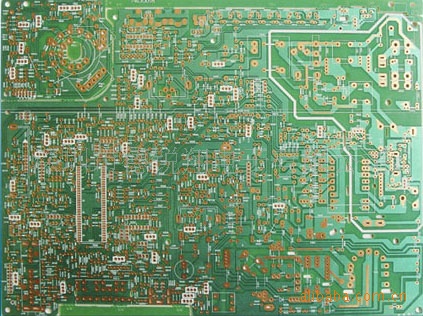

SMT (Surface Mount Technology), also known as Surface Mount Technology, is a modern electronic manufacturing technology.

SMT surface mount technology is mainly used to mount electronic components onto printed circuit boards (PCBs). Compared with traditional plug-in technology, SMT surface mount has many advantages. Firstly, SMT patches can achieve miniaturization and high-density assembly of electronic components. Due to the fact that electronic components can be directly mounted on the surface of PCBs without the need for plug-in holes, the size and weight of PCBs can be greatly reduced, thereby improving the integration of electronic devices.

Secondly, SMT surface mount technology has the characteristics of high efficiency and high degree of automation. SMT surface mount machines can quickly and accurately mount electronic components onto PCBs, greatly improving production efficiency. Meanwhile, SMT surface mount technology can achieve fully automated production, reducing manual operations and lowering production costs.

The process of SMT mounting mainly includes the following steps: Firstly, clean and pretreat the PCB to ensure surface flatness and cleanliness. Then, the solder paste is printed on specific positions on the PCB using a printing machine. The function of solder paste is to fix electronic components during the soldering process and provide good conductivity. Next, use a placement machine to accurately mount electronic components onto the solder paste positions on the PCB. Surface mount machines typically use high-precision robotic arms and vision systems to achieve fast and accurate mounting. Finally, send the PCB with electronic components attached to it into a reflow soldering oven for soldering. In a reflow soldering oven, solder paste melts at high temperatures, firmly soldering electronic components and PCBs together.

SMT surface mount technology also has relatively high requirements for electronic components. Electronic components need to have characteristics such as miniaturization, high precision, and high reliability to meet the production requirements of SMT surface mount. At the same time, SMT surface mount technology also requires the use of high-quality solder paste, PCB materials, etc. to ensure soldering quality and product reliability.

In short, SMT surface mount technology is an advanced electronic manufacturing technology with advantages such as miniaturization, high-density assembly, high efficiency, and high degree of automation. With the continuous development of electronic technology, the application of SMT surface mount technology in the field of electronic manufacturing will become increasingly widespread.

Or call +86 755 2794 4155

Inquiry Now