+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-08-10

2024-08-10

417

417

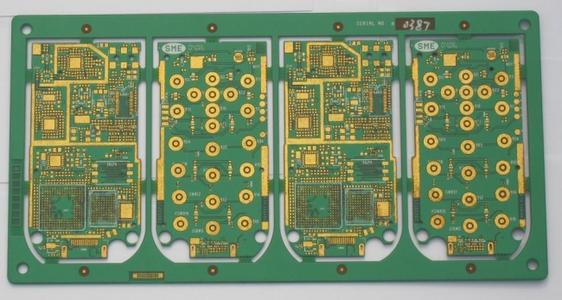

Low cost prototype PCB assembly

In the development process of modern electronic products, prototype PCB (printed circuit board) assembly is an indispensable part. Cost control is particularly important for startups and individual developers. Low cost prototype PCB assembly can not only save expenses, but also accelerate the speed of product launch. The key to achieving low cost lies in selecting suitable materials, optimizing design, and mass production.

Firstly, choosing materials with lower costs but reliable quality is an effective way to reduce costs. For example, using standard FR-4 substrates instead of more expensive high-frequency materials can reduce material costs while ensuring performance. Secondly, optimizing circuit design can reduce the number of components and circuit board area, thereby reducing manufacturing costs. In addition, planning the circuit layout reasonably and avoiding complex multi-layer board designs can significantly reduce costs.

Mass production is another important strategy for reducing costs. By negotiating with PCB manufacturers and selecting an appropriate minimum order quantity (MOQ), one can obtain price discounts while ensuring quality. In addition, select competitive suppliers and manufacturers to further reduce manufacturing costs through price comparison and negotiation.

In summary, low-cost prototype PCB assembly requires comprehensive consideration of material selection, design optimization, and mass production to achieve the optimal balance between cost and performance.

Or call +86 755 2794 4155

Inquiry Now