+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-07-27

2024-07-27

993

993

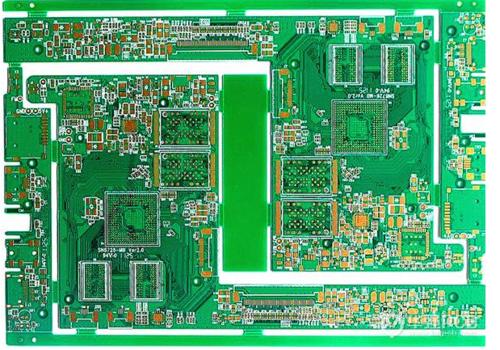

Through-hole printed circuit board

Through Hole PCB is a traditional type of circuit board, characterized by the connection between the pins of components and the copper foil of the circuit board through drilling and soldering. Through hole technology was widely used from the 1960s to the 1980s, and although modern circuit boards are increasingly adopting surface mount technology (SMT), through hole technology still holds an important position in certain applications.

The main advantages of through-hole technology are high mechanical strength and reliable electrical connections. Due to the fact that the pins of the components pass through the circuit board and are soldered to the other side, this connection method can withstand significant mechanical stress and high temperature environments. Therefore, through-hole PCBs are commonly used in fields such as industrial control, automotive electronics, and aerospace, which require high stability and durability of circuit boards.

The process of manufacturing through-hole PCBs includes steps such as drilling, electroplating, etching, and soldering. Drilling is a crucial step, and the diameter and position of the hole must be precise and error free. The electroplating process deposits a layer of metal on the inner wall of the hole to achieve electrical connection. Modern through-hole PCB manufacturing technology also includes laser drilling and electroless copper plating to improve accuracy and quality.

Although through-hole technology is not as advanced as surface mount technology in some aspects, it is still indispensable. In hybrid assembly, through-hole technology and surface mount technology are often combined to meet the needs of different components and circuits.

Or call +86 755 2794 4155

Inquiry Now