+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

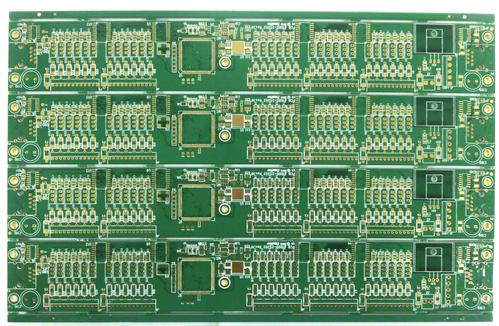

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-11-27

2023-11-27

289

289

PCB circuit board impedance refers to the parameters of resistance and reactance, which hinder AC power. In the production of PCB circuit boards, impedance processing is essential. The reasons are as follows:

1. PCB circuits (bottom of the board) should consider the installation of electronic components by plugging, and after plugging, issues such as conductivity and signal transmission performance should be considered. Therefore, it is required that the impedance should be as low as possible, and the resistivity should be less than 1&TIMes per square centimeter; Below 10-6.

2. During the production process of PCB circuit boards, they need to go through processes such as copper deposition, electroplating tin (or chemical plating, or thermal spraying tin), and connector soldering. The materials used in these processes must ensure a low resistivity to ensure that the overall impedance of the circuit board meets product quality requirements and can operate normally.

3. The tin plating of PCB circuit boards is the most common problem in the entire circuit board production process, and it is a key link that affects impedance. The biggest defects of chemical tin plating layer are easy discoloration (easy oxidation or deliquescence), poor solderability, which can lead to difficulty in soldering circuit boards, high impedance, poor conductivity, or unstable overall board performance.

4. There are various signal transmissions in the conductors of a PCB circuit board. When it is necessary to increase its frequency in order to improve its transmission rate, the impedance value of the circuit itself will change due to factors such as etching, stack thickness, wire width, etc. This will cause signal distortion, leading to a decrease in the performance of the circuit board. Therefore, it is necessary to control the impedance value within a certain range.

Or call +86 755 2794 4155

Inquiry Now