+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-09-15

2023-09-15

488

488

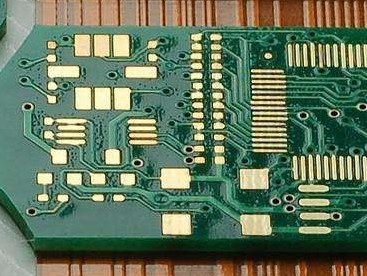

Wave soldering is a batch soldering process used for manufacturing PCBs. The basic equipment used in this process is to move PCB through conveyors in different areas, solder trays used in the welding process, pumps that generate actual waves, and spray and preheating pads for flux. Solder is usually a mixture of metals. Wave soldering is mainly used for welding through hole components.

1. There is green oil inside the component hole, which leads to poor tin plating inside the hole. The green oil in the hole should not exceed 10% of the hole wall, and the number of holes in the internal green oil should not exceed 5%.

2. Insufficient coating thickness leads to poor tin plating in the hole.

3. The coating thickness on the component hole wall is insufficient, resulting in poor tin plating inside the hole. For example, copper thickness, tin thickness, gold thickness, etc. Usually, the thickness of the hole wall should be greater than 18 μ M.

4. The hole wall is too rough, resulting in poor tin plating or pseudo welding inside the hole. If the hole wall is too rough, the coating will be uneven; Some coatings that are too thin can affect the effect of tin coating.

5. The hole is damp, causing pseudo welding or bubbles. Sealing the PCB before drying or cooling, as well as leaving it for a long time after unpacking, can lead to moisture in the holes, false soldering or bubbles.

6. The size of the pad is too small, resulting in poor welding.

7. The interior of the hole is dirty, resulting in poor welding. Insufficient PCB cleaning, such as the gold plate not being pickled, can result in impurities and dirt residue on the holes and pads, affecting the tin effect.

8. Due to the small size of the hole, the component cannot be inserted into the hole, resulting in welding failure.

9. Due to the offset of the positioning hole, the component cannot be inserted into the hole, resulting in welding failure.

Or call +86 755 2794 4155

Inquiry Now