+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-05-13

2023-05-13

826

826

1. Line and Pattern (Pattern): The line is a tool for turning between the original. In the design, the design will be designed as a large copper surface as the ground and power layer. The lines and the diagram are made at the same time.

2. Throughhole/VIA: The guide holes can turn the lines above two levels of lines, and the larger guide holes are used as parts plug -in. Putting and positioning, fixed screws during assembly.

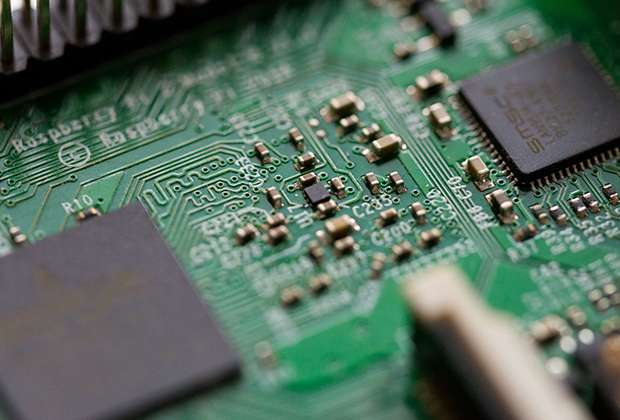

Industrial control circuit board

3. SolderResistantant/SolderMask: Not all copper noodles have to eat tin parts, so it will printed a layer of substances from copper noodles (usually epoxy resin) to avoid Non -short circuit between the lines of tin. According to different processes, it is divided into green oil, red oil, and blue oil.

4. Dielectric: It is used to maintain the insulation between lines and layers, commonly known as substrate.

5. Legend/Marking/Silkscreen: This is a non -necessary composition. The main function is to mark the names and position boxes of each part on the circuit board to facilitate the repair and identification after assembly.

6. Surface treatment (SurfaceFinish): Because the copper surface is easily oxidized in general environments, it cannot be used to be protected on the copper surface of the tin. The protection method is tin spray, chemical (enig), iMmersionSilver, Immersion Tin, organic welding (OSP), each has its own advantages and disadvantages, collectively referred to as surface processing.

Or call +86 755 2794 4155

Inquiry Now