+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-11-17

2023-11-17

271

271

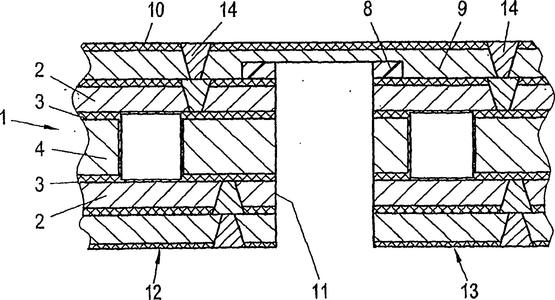

The so-called blind hole circuit board refers to non drilled holes. The difference between blind holes and through holes is that through holes are holes drilled through each layer. When making blind hole boards, drilling is done before pressing, while through holes are drilled after pressing. What basic knowledge do you need to know in the manufacturing of blind hole PCB circuit boards

Blind hole PCB circuit board

① Drill tape: Select through holes as unit reference holes. Each blind hole drill tape needs to select a hole and identify its corresponding unit reference hole coordinates, and note which drill tape corresponds to which layers. When the laser hole is sleeved with the inner buried hole, even if the holes of the two drill tapes are in the same position, it is necessary to confirm with the customer. Move the position of the laser hole to ensure electrical connection, and do not handle it arbitrarily based on experience.

② Process holes: The inner layer of ordinary multi-layer boards does not need to be drilled. Process holes only need to be made when making blind hole circuit boards. All tooling holes on blind hole boards are drilled, and attention should be paid to rivets; To avoid alignment deviation, it is necessary to drill characters on the edges of the production PNL board to distinguish each board.

③ Film modification: Note that the film produces positive and negative films. If the plate thickness is greater than 8mil (without copper connection), the positive film process is used, and if it is less than 8mil (without copper connection), the negative film process is used. When the wire thickness/gap valley is large, the copper thickness at d/f should be considered instead of the bottom copper thickness.

④ Production process: The only difference between a blind hole board and a buried through hole is that one side is on the outer layer and needs to be made with a single side d/f. Be careful not to roll the wrong side (when the double-sided bottom copper is inconsistent); During d/f exposure, the bare copper surface is covered with black tape to prevent light transmission. As the blind hole plate is located on one side of the plate surface and on the inner layer, it is necessary to make more than two measurements of the plate thickness. Therefore, the plate thickness and copper thickness should be controlled, and the range of copper thickness should be indicated after etching. After pressing the plate, target holes should be made for multi-layer plates using an X-ray machine.

Or call +86 755 2794 4155

Inquiry Now