+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-11-01

2023-11-01

633

633

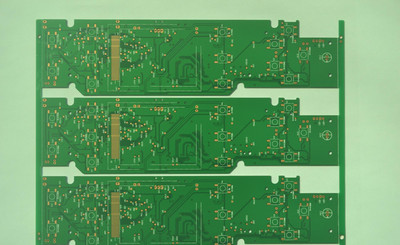

The production process of automotive circuit boards involves numerous materials and processes, requiring rigorous design and precise manufacturing. Firstly, the designer will design a circuit diagram that meets the performance and control requirements of the car. Then, the circuit diagram will be converted into a physical circuit board substrate, which requires the use of a high-precision exposure technology called "light drawing".

Next, the circuit board substrate will undergo copper plating treatment to form a conductive circuit path. Then, various electronic components such as capacitors, resistors, diodes, transistors, etc. will be soldered onto the channel. Finally, these circuit boards will be tested and debugged to ensure that their performance meets the actual usage needs of the car.

The maintenance and upkeep of car circuit boards is very important, otherwise it may affect the normal operation of the car and even cause malfunctions. Firstly, users should avoid using cars in environments with high humidity, as moisture can cause corrosion to circuit boards. In addition, various connection points and interfaces on the circuit board should be regularly cleaned and maintained to avoid increased resistance or short circuits caused by dust or other foreign objects.

Secondly, when operating the car, users should avoid switching electrical equipment too frequently to reduce the load and damage on the circuit board. Finally, it is also necessary to regularly inspect and test the circuit board, in order to promptly identify and solve problems and avoid causing greater losses.

Or call +86 755 2794 4155

Inquiry Now