+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-09-23

2023-09-23

597

597

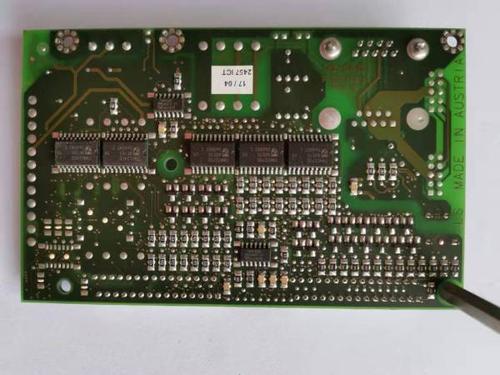

From PCB circuit board design to the completion of all component welding to a high-quality circuit board, it requires strict control from PCB design engineers, as well as the level of welding processes and workers. There are mainly the following factors: PCB board drawing, circuit board workmanship quality, device quality, oxidation degree of device pins, solder paste quality, printing quality of solder paste, accuracy of program programming of the SMT machine, mounting quality of the SMT machine, setting of temperature curve of the reflow soldering furnace, and other factors that may affect poor PCB soldering.

The process of PCB drawing is an insurmountable part of the PCB chip welding factory itself. Due to the fact that circuit designers often do not solder circuit boards, they cannot gain direct welding experience and are unaware of the various factors that affect welding; The workers in the welding factory do not understand the drawing board, they only focus on completing production tasks, and have no mentality or ability to analyze the reasons for poor welding. Due to the respective roles of these two talents, it is difficult to organically combine them. In the end, most of the reasons for failure are still in communication.

Below, I will provide some suggestions to the PCB drawing design and wiring engineers regarding the PCB drawing process, hoping to avoid various poor drawing methods that affect the welding quality during the drawing process. It will mainly be introduced in the form of graphics and text.

Or call +86 755 2794 4155

Inquiry Now