+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-12-04

2023-12-04

381

381

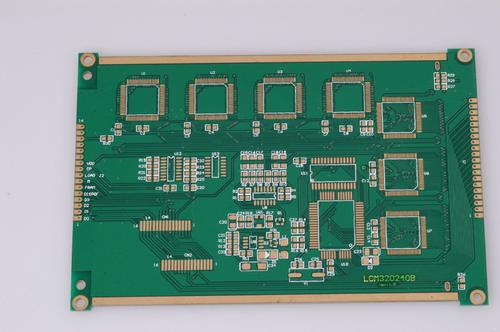

SMT processing is the most common technology in the SMT processing industry. What questions do we need to know about such a process? How can we comprehensively understand the technology of SMT processing? How can we comprehensively understand the factors that contribute to these problems? Here are a few points for you:

1: Placement of SMT processing: Its function is to accurately install surface mounted components onto the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

2: Screen printing for SMT processing: Its function is to leak solder paste or SMT adhesive onto the PCB pad, preparing for the welding of components. The equipment used is a screen printing machine (screen printing machine), located at the forefront of the SMT production line.

3: Solidification of SMD processing: Its function is to melt the SMD adhesive, thereby firmly bonding the surface assembled components with the PCB board. The equipment used is a curing furnace, located behind the SMT production line SMT placement machine.

4: Glue dispensing for SMT processing: It drops glue onto the fixed position of the PCB, and its main function is to fix the components onto the PCB board. The equipment used is a dispensing machine, located at the forefront of the SMT production line or behind the testing equipment.

Or call +86 755 2794 4155

Inquiry Now