+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-01-17

2024-01-17

573

573

In the manufacturing process of printed circuit boards, there are many processes involved, and each process may have quality defects. These quality issues always involve many aspects, which can be difficult to solve. As the causes of problems are multifaceted, some belong to chemical, mechanical, sheet metal, optical, and other aspects. After decades of production practice, combined with practical experience in solving quality problems and relevant information on solving technical problems, the following summary is made:

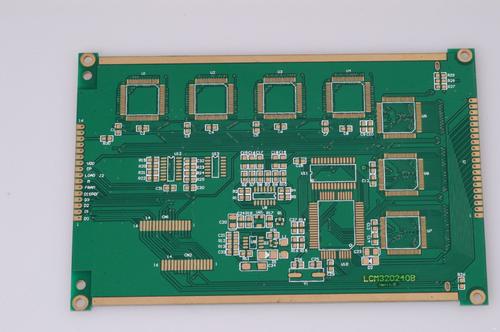

Defects, causes, and solutions in the manufacturing process of printed circuit boards

Solution to the causes of defects in the process

There are blisters on the facial mask layer of the film sticking board. The board surface is not clean. Check the wettability of the board surface, that is, the clean surface can keep the water even and the continuous water film lasts for up to 1 minute

Low film temperature and pressure increase temperature and pressure

The edge of the membrane layer is raised due to the excessive tension of the membrane layer, resulting in poor adhesion of the membrane layer. Adjust the pressure screw

Poor contact between the wrinkled film layer and the board surface, locking pressure screw

Poor exposure resolution ability due to scattered and reflected light reaching the covered area of the film layer, reducing exposure time

Overexposure reduces exposure time

Image difference between yin and yang; The low sensitivity results in a minimum shade to shade ratio of 3:1

Poor contact inspection between film and board surface, vacuum pumping system

Adjust again if the light intensity is insufficient after adjustment

Or call +86 755 2794 4155

Inquiry Now