+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-06-18

2024-06-18

365

365

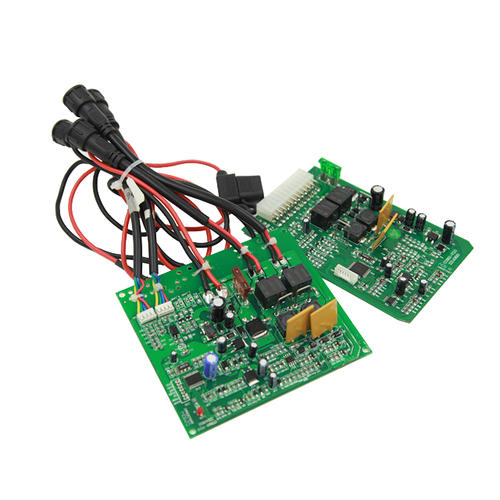

The assembly of electronic products poses significant challenges to production scheduling due to the large number and variety of components, as well as the short lifespan of electronic products. Multi variety, small batch, and variable batch production have become the mainstream production mode in electronic manufacturing. In this mode, the switching time between multiple varieties occupies an increasingly large proportion of the entire assembly time.

Composed of a high-speed SMT machine and a multifunctional SMT machine. In fact, the entire PCB assembly line also includes equipment such as feeding machines, screen printing machines, dispensing machines, reflow soldering and curing furnaces, and take-up machines. These devices are connected in series to form the PCB assembly line, but these auxiliary devices do not constitute the bottleneck process of the entire assembly line, so they are omitted during modeling. Each SMT machine can accommodate 20 feeding slots, and each component occupies one feeding slot on the SMT machine. Generally speaking, the number of component types required for a single variety of PCBs does not exceed the capacity of the feeder, but the total number of component types required for multiple varieties of PCBs usually exceeds the capacity of the feeder.

During the mounting process, the components required for different types of PCBs are placed on these feeding slots, and the mounting device removes the components from the feeding slots and attaches them to the designated position on the PCB. According to the survey data of empirical research subjects, the average time for high-speed SMT machines to install a component is 0.06s, and the average time for switching to a feeding slot is 180s. The multifunctional SMT machine has two workstations, but only one workstation works, and the other workstation is only used to place large or irregular components. Each workstation accommodates 10 feeding slots, and it takes an average of 0.18 seconds to install one component. The average time to switch between one feeder is 220 seconds. When switching between different types of PCBs, the SMT machine requires a certain amount of preparation time for switching, usually about 6 times the time for switching to a component feeding slot, which is 1200s. It can be seen that switching time plays a crucial role in the assembly process of electronic products.

Or call +86 755 2794 4155

Inquiry Now