+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

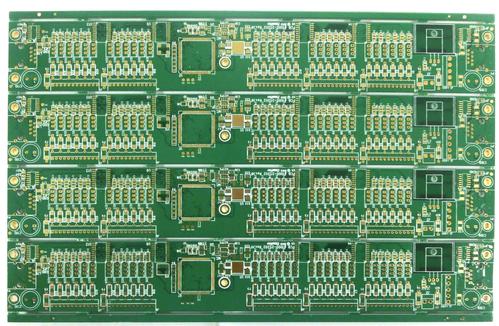

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-05-26

2023-05-26

610

610

The first PCB uses a hole technology, inserts the hole on one side of the circuit board through the lead, and welded the circuit component to the bronze traces on the other side. The board can be single -sided, with an unpopular component side, or a more compact double panel, welded with components on both sides. By bending 90 degrees in the same direction in the same direction, inserting parts into the circuit board (usually a curved lead on the back of the circuit board), can be installed horizontally with two axial leads (such as resistors, capacitors, and diode). Essence Provide boards in the opposite direction to improve the mechanical strength of parts), welded the lead, and trim the end. The lead can be welded manually or welded with a peak welding machine. Tongkou manufacturing increases the cost of the circuit board by requiring accurate drilling, and limits the available wiring area of the signal wiring on the front of the top layer on the top layer of the top layer of the multi -layer circuit board, because these holes must reach the opposite side through all layers. Once the surface is installed and put into use, use small SMD components as much as possible. Due to power requirements or mechanical restrictions, only components are not suitable for surface installation, or mechanical stress that may damage PCB (for example, the copper is lifted from the surface of the circuit board to lift the surface of the board plate. .

Or call +86 755 2794 4155

Inquiry Now