+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-06-01

2023-06-01

745

745

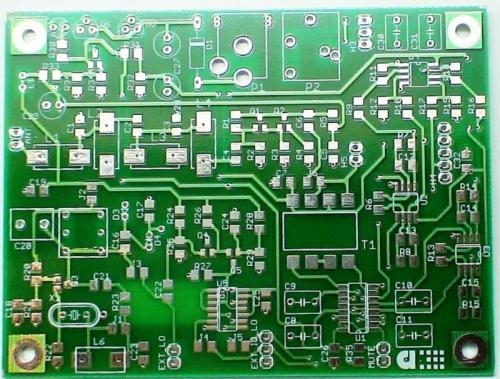

It is important to develop a steady test strategy to develop a stable test strategy to ensure the compliance and function of designing a stable test strategy to ensure the compliance and function of designing. In addition to the establishment and testing of these complex assembly, the money invested in electronic parts may be very high -when a unit can reach $ 25,000 when the final test is at the final test. Because of this high cost, the problem of finding and repairing assembly is more important than its past and even more important steps. Today, the more complicated assembly is about 18 square inch inch, 18 floors; there are more than 2,900 components on the top and bottom; it contains 6,000 circuit nodes; more than 20,000 welding points need to be tested.

In Langxun Accelerated Manufacturing Factory (N. Andover, MA), manufacturing and testing art -level PCBAs and complete transmission systems. The assembly of more than 5,000 nodes is a concern for us because they are close to our existing online test (ICT, In Circuit Test) device (Figure 1). We make about 800 different PCBAs or "nodes". Among these 800 nodes, about 20 species are in the range of 5,000 ~ 6,000 nodes. However, this number has grown rapidly.

New development projects require more complex and larger PCBA and closer packaging. These requirements to challenge our capabilities to build and test these units. Further, a larger circuit board with smaller components and higher nodes may continue. For example, there are about 116,000 nodes, more than 5100 components, and more than 3,7800 requirements for testing or confirmation of welding points in the design of the design of the circuit board diagram. This unit also has BGA on the top and bottom surface, and BGA is followed by. Testing this size and complex board with traditional needle beds is impossible.

In the manufacturing process, especially in testing, the continuous PCBA complexity and density are not a new problem. The increase in the number of test stitches in the ICT test fixture is not to go. We began to observe the replaceable circuit confirmation method. Seeing the number of non -contact per million probes, we found that when 5,000 nodes, many found errors (less than 31) may be due to the exposure problem of probe instead of actual manufacturing (Table 1). Therefore, we started to reduce the number of test needles instead of rising. Nevertheless, the quality of our manufacturing process is still evaluated to the entire PCBA. We decided to use the traditional ICT and X -ray layering method is a feasible solution

Or call +86 755 2794 4155

Inquiry Now