+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-09-13

2023-09-13

310

310

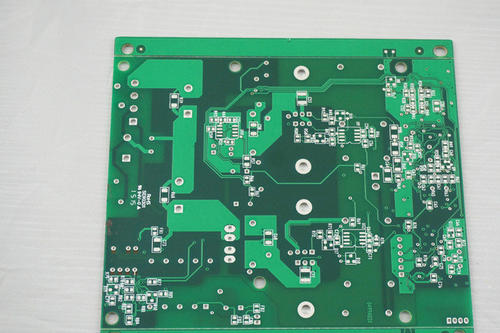

Copper deposition is the abbreviation for chemical copper plating, also known as through hole plating, abbreviated as PTH. It refers to the chemical deposition of a thin layer of chemical copper on a non conductive hole wall substrate that has been drilled, to serve as the substrate for subsequent copper plating. So, what are the processes for copper deposition on PCB circuit boards? Let's take a look together with the editor:

1、 Decomposition of PTH process:

Alkaline degreasing → Second or third stage countercurrent rinsing → Coarsening (micro etching) → Second stage countercurrent rinsing → Pre leaching → Activation → Second stage countercurrent rinsing → Gelation → Second stage countercurrent rinsing → Copper precipitation → Second stage countercurrent rinsing → Acid leaching.

2、 Detailed process explanation of PTH:

1. Alkaline degreasing: Remove oil stains, fingerprints, oxides, and dust inside the holes on the board surface; Adjust the pore wall from negative charge to positive charge, facilitating the adsorption of colloidal palladium in subsequent processes; After oil removal, it is necessary to strictly follow the instructions for cleaning, and use a copper deposition backlight test for detection.

2. Micro etching: Remove oxides from the board surface, roughen the board surface, and ensure good adhesion between the subsequent copper deposition layer and the substrate copper.

3. Pre impregnation: Mainly used to protect the palladium tank from contamination by pre-treatment tank solution, extend the service life of the palladium tank, and facilitate timely entry of subsequent activation solution into the pores for sufficient and effective activation.

4. Activation: After adjusting the polarity of alkaline oil removal through pre-treatment, the positively charged pore wall can effectively adsorb enough negatively charged colloidal palladium particles to ensure the average, continuity, and density of subsequent copper deposition.

5. Gel release: Remove the tin ions wrapped around the colloidal palladium particles, expose the palladium nuclei in the colloidal particles, and directly and effectively catalyze the initiation of chemical copper deposition reaction.

6. Copper precipitation: Through the activation of palladium nuclei, a chemical copper precipitation self catalytic reaction is induced. The newly formed chemical copper and reaction byproduct hydrogen can both serve as reaction catalysts to catalyze the reaction, allowing the copper precipitation reaction to continue continuously. During the process, the tank liquid should be stirred with normal air to convert more soluble divalent copper.

Or call +86 755 2794 4155

Inquiry Now