+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-05-24

2023-05-24

445

445

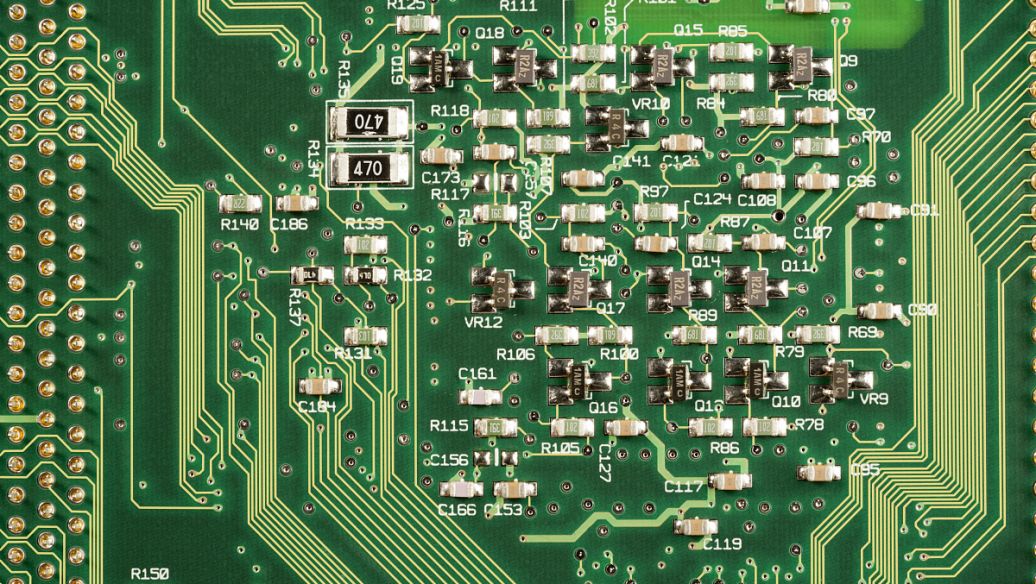

The testability design of a good product can simplify the preparation of inspection and product final testing in the production process, improve test efficiency, reduce test costs, and easily find the product defects and faults, thereby ensuring the quality stability and reliable quality of the product. sex.

1. Testability of PCB design

Like the manufacturing design of PCB, the testability design of PCB also belongs to the processing design of the printed board, which also includes the testability of the printed board manufacturing and finished printing board (light board) Two parts of testability, the test methods and requirements of these two parts are completely different. For the designer of PCB, it is necessary to understand both the performance and testing methods that need to be tested on the printed board, and to understand the installation test requirements and test methods of the printed board assembly parts.

With the miniaturization of electronic products, the online testing of printing board assembly is becoming more and more difficult. Therefore, when designing, it is necessary to fully consider the testable electrical conditions and physical and mechanical conditions of printed boards, as well as appropriate mechanical electronic equipment.

2. PCB's light board test

The PCB's light board test is an important means to ensure the quality of the printing board to be installed, and it is also an important link to ensure the quality of the components of the printing board and reduce the loss of repairs, rework and waste. The electronic industry at home and abroad attaches great importance to the tests of the performance of the printing board. The main testing items include appearance testing, mechanical performance testing, electrical performance testing, physical chemical performance testing, and reliability (environmental adaptability) testing.

Or call +86 755 2794 4155

Inquiry Now