+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2023-07-27

2023-07-27

311

311

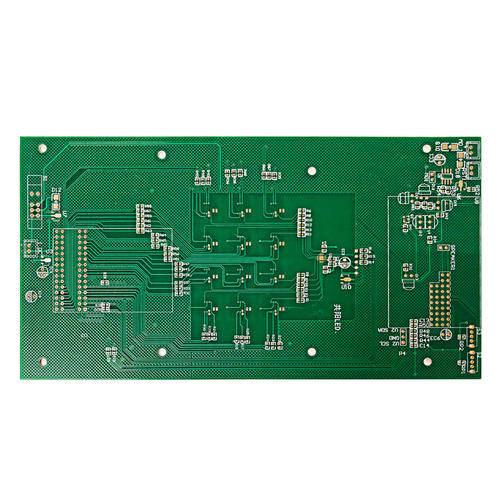

The level of PCB engineering production can reflect the design level of designers, as well as the production process and technical level of printed board manufacturers. At the same time, as the PCB engineering production integrates Computer-aided design and auxiliary manufacturing, it requires extremely high precision and accuracy, otherwise it will affect the electrical performance of the final electronic products on board, and may cause errors in serious cases, which will lead to the scrapping of the whole batch of printed board products, delay the manufacturer's contract delivery time, and suffer economic losses. Therefore, as a PCB engineering manufacturer, one must always bear in mind their significant responsibilities and not take them lightly. They must be careful, serious, and meticulous. When processing PCB design files, it is important to carefully check whether the received files comply with the rules established by the designer? Can it meet the requirements of PCB manufacturing process? Is there a positioning mark? Is the route layout reasonable? Is the distance between wire and wire, wire and component solder pads, wire and through-hole, component solder pads and through-hole, and through-hole reasonable and able to meet production requirements. Are there any conflicts between components in 2D or 3D space? Is the size of the printed board consistent with the processing drawings? Will the graphics added to the PCB graphics (such as icons and labels) cause a signal short circuit. Edit and modify some unsatisfactory linear shapes. Is there a process line added to the PCB? Whether the resistance welding meets the requirements of the production process, whether the resistance welding size is appropriate, and whether the character mark is pressed on the device solder pad to avoid affecting the quality of the electrical installation.

Or call +86 755 2794 4155

Inquiry Now