+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

-

Shenzhen KNOWNPCB Technology Co., Ltd.

+86 755 2794 4155

+86 755 2794 4155  sales@knownpcb.com

sales@knownpcb.com

2024-02-23

2024-02-23

917

917

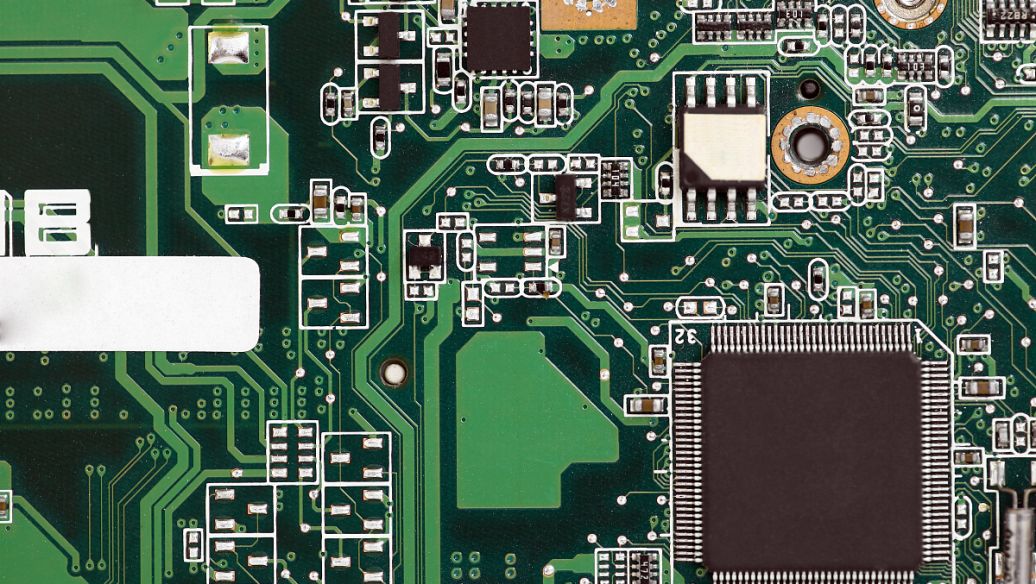

The so-called copper coating refers to using the idle space on the PCB as a reference plane, and then filling it with solid copper. These copper areas are also known as copper filling. Copper coating can be divided into large-area copper coating and grid copper coating. Next, let professional PCB manufacturers provide you with a detailed understanding of the basic knowledge of PCB circuit board copper coating:

1、 Precautions for copper coating:

1. Single point connection in different locations: connected through a 0 ohm resistor, magnetic bead, or inductor.

2. The copper coating near the crystal oscillator is used as a high-frequency emission source in the circuit. The crystal oscillator should be surrounded by copper coating, and then the outer shell of the crystal oscillator should be grounded separately.

2、 What are the benefits of copper coating?

1. Copper coating can reduce ground wire impedance and improve anti-interference ability;

2. Reduce voltage drop and improve power efficiency;

3. Connect to the ground wire to reduce the loop area.

3、 Is it better to cover a large area with copper or a grid with copper?

This issue cannot be generalized, it should be analyzed on a specific issue, regardless of which one is better. For example, when starting wiring, the ground wire should be treated equally. When wiring, the ground wire should be properly routed. If a grid covered with copper is used at this time, these ground wires will affect aesthetics. However, with a large area of copper coating, the board may curl up and even bubble during wave soldering. From this point of view, the heat dissipation of grid copper coating is better. Usually, high-frequency circuits require high anti-interference requirements for multi-purpose grid copper coating, while low-frequency circuits with high current circuits commonly use complete large-area copper coating.

Or call +86 755 2794 4155

Inquiry Now